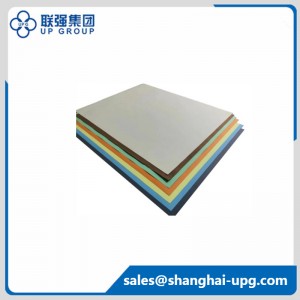

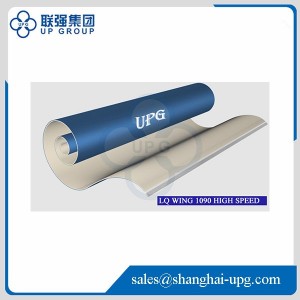

NL 627 Type Printing Blanket

Product Features

Traditional soft butyl surface designed for use with modern UV curinginks and cleaning solutions.

High quality and durable, provides extra robustness.

Technical data

|

Thickness: |

1.96±0.02mm |

||||

|

Colour: |

Black |

Construction: |

4 ply fabric |

||

|

Compressible layer: |

Microspheres |

||||

|

Microhardness: |

55° |

||||

|

Surface finish : |

Smooth Cast |

||||

|

True Rolling (Paper feed characteristics): |

Positive | ||||

|

Ink compatibility: |

UV and IR Curing plastic container printing inks | ||||

Advantages of NL 627

Our soft butyl surfaces are specifically designed to work seamlessly with modern UV-curable inks and cleaning solutions. Its traditional soft butyl finish combined with premium materials provides extra sturdiness, ensuring long-lasting performance and reliability. This makes it ideal for printers looking to enhance their printing capabilities and achieve superior results.

One of the key features of our soft butyl surface is its ability to enhance ink transfer on difficult materials and profiles. Its soft surface is designed to improve ink adhesion and transfer, making it suitable for use on textured surfaces and irregular shapes. This is especially beneficial for printers working with challenging substrates, as it allows for more consistent and precise print results.

Additionally, our soft butyl surface is designed for use with ketone and UV-curable inks, making it a versatile solution for a variety of printing applications. Whether you use traditional or modern printing processes, our soft butyl surfaces are engineered to deliver superior performance and reliability, ensuring consistent, high-quality results every time.

Additionally, our soft butyl surface is suitable for slower printers, providing excellent ink transfer and stability even at lower print speeds. This makes it the ideal printer for those looking to achieve precise and detailed print results without compromising on quality or efficiency.

Our soft butyl surface’s thick stable fabric further enhances its durability and performance, ensuring it can withstand the rigors of daily printing operations. This makes it a cost-effective solution for printers as it reduces the need for frequent replacement and maintenance, ultimately saving time and resources.

● Soft surface can enhance ink transfer on difficult materials and profiles.

● Suitable for slower presses.

● Thick stabilising fabric.

● Soft butyl surface.

● Specially designed for ketone and UV curing inks.

● Can enhance ink transfer on e.g. textured surfaces and irregular shapes.

● High quality and durable, provides extra robustness.

Pre-sales Q&A

| Question | Answer |

| 1.What types of printing blanket are there? | Common types include full air cushion, air cushion, three-in-one, traditional, UV special, local gloss, metal printing 2PSC, wear-resistant, paper cup special, UV self-adhesive, report machine self-adhesive, aluminum strip, etc. |

| 2.How to choose the right printing blanket? | It is selected according to the type of printing machine, material of printed products, printing technology (such as UV printing, metal printing, etc.), printing quality requirements (such as dot reduction, ink transfer, etc.) and printing environment, etc. |

| 3. Does the thickness of blanket affect printing? | It has influence. The thickness will affect the distribution of printing pressure and the transfer effect of ink. Different printing machines and printing requirements have different requirements for blanket thickness. |

| 4. What is the function of surface treatment of blanket? | Surface treatment can improve the ink transfer performance, wear resistance, chemical resistance and so on of blanket, so as to improve printing quality and extend service life. |

| 5. How long is the life of blanket? | The life depending on the frequency of use, printing conditions, maintenance and other factors. |

| 6.Is the price difference of blanket large? | The price difference is large, mainly affected by material, process, brand, specification and other factors. |

| 7. What should be paid attention to when installing blanket? | When installing, make sure the blanket is flat, no wrinkles, no bubbles, and adjust the pressure and tension correctly. |

| 8.What are the storage requirements for blanket? | It should be stored in a cool, dry environment away from heat sources and avoid direct sunlight. It is best to place it flat or hang it on a pole. |

| 9.What are the suggestions for cleaning and maintaining blanket? | After printing, it should be cleaned in time to avoid the accumulation of ink, paper scraps and other residues; Check the surface of the blanket regularly for damage or aging. |

| 10.What information is required when purchasing blanket? | The printing machine model, printing paper type, printing process requirements, printing quality requirements and other information should be provided. |

After sale Q&A

| Question | Answer |

| 1.What should do if the printing area of blanket is blurred and not complete? | Check whether the printing pressure is accurate, whether the pad is damaged, whether the blanket is damaged by impact, whether the printing plate is blind, and replace the blanket when necessary. |

| 2.What is the reason for the blanket strip to fall off? | It may be due to the blanket being stretched too tightly, the installation of the strip is not proper, the use of the strip is not proper or the installation on the printing machine drum roller shaft is not proper. |

| 3.How to solve the swelling of blanket surface? | Check the thickness of the blanket and lining, clean regularly with a high quality cleaning agent, and replace if the blanket is old or not suitable for the ink used. |

| 4.What is the cause of printing dot shadow? | It may be due to improper installation of blanket, excessive printing pressure, too much ink or plate dot movement. |

| 5. What should do if the blanket is de-layered with ink? | Check whether the blanket is corroded by solvent, whether it is squeezed too much, whether the ink is piled up at the edge, etc., and replace the blanket when necessary. |

| 6.What is the reason for the increase of printing dots? | It may be due to the excessive pressure of the ink roller, too low hardness, improper selection of ink, imbalance between ink and water, excessive pressure between printing plate and blanket cylinder, and between blanket and impression cylinder. |

| 7.How to deal with the accumulation of paper dust and paper powder on the surface of blanket? | Blanket should be cleaned in time to keep its surface clean and prevent the accumulation of impurities from being too thick to lose the elasticity of rubber layout. |

| 8. What should do if the blanket is aging? | Blanket should be replaced in time, and its storage and use environment should be checked to see if it meets the requirements. |

| 9.What if the tension of the blanket is not enough? | The tension of the blanket needs to be readjusted to ensure good contact with the plate throughout the printing process. |

| 10.What should do when the blanket life is over? | New blanket should be replaced in time, and the old blanket should be properly handled. |