Printing is a key element in the field of printing that directly affects the quality and efficiency of printing. A printing plate is a thin, flat metal, plastic or other material that is used in the printing industry to transfer ink to a printed object such as paper or cardboard to form a printed piece. The type of printing plate used can greatly affect the final output, so it is vital to choose the right material, this article will introduce the various materials that can be used as printing plates and their suitability in different printing applications.

Traditionally, printing plates are made from metals such as lead or steel. These metal plates are very durable and can withstand the stress and wear and tear of the printing process, making them ideal for high volume printing jobs. However, metal printing plates are expensive to produce and difficult to recycle, which raises environmental concerns. As a result, alternative materials have been developed to address these issues and provide a more sustainable option for printing plates.

One such alternative material is plastic, and plastic printing plates offer a number of advantages, including low production costs and flexibility in design and customisation. They are lighter than metal plates and easier to handle and transport. In addition, plastic boards can be recycled, reducing their impact on the environment. However, plastic printing plates may not be as durable as metal plates and may not be suitable for all types of printing processes.

Another material that can be used as a printing plate is photopolymer. Photopolymer plates are made from a photopolymer material that hardens when exposed to UV light. These plates can be made using a photographic process and can accurately reproduce intricate designs and fine details. Photopolymer plates are commonly used for flexographic printing, a common method of printing packaging materials and labels. They have excellent ink transfer characteristics and can be used with a wide range of inks and substrates, making them a versatile choice for many printing applications.

In recent years, digital printing technology has advanced by leaps and bounds, fuelling the growth of digital printing. These plates are used in digital presses, eliminating the need for traditional plates altogether. Instead, the image to be printed is transferred directly from the text file to the print substrate, eliminating the need for a physical printing plate. Digital printing plates offer the advantages of quick set-up, low waste and economical printing of small quantities. They are particularly well suited to personalisation and print on demand, making them a popular choice for marketing materials such as brochures, leaflets and direct mail campaigns.

In addition to the above, there are a number of unconventional materials that can also be used as printing plates, such as cardboard, foam and even fruit and vegetables, and these alternative printing plates are often used in artistic or experimental printing processes, with the aim of achieving unique and very traditional visual effects. Printing with fruits and vegetables, for example, becomes "nature printing" and can produce organic textures and patterns that are difficult to replicate with traditional printing plates. While these non-traditional materials may not be suitable for commercial printing, they offer creative possibilities for artists and designers who wish to push the boundaries of traditional printing techniques.

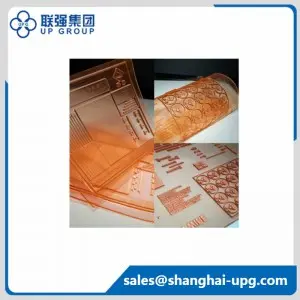

Our company also produces printing plates, such as this one LQ-FP Analog Flexo Plates for Carton (2.54) & Corrugated

• suitable for a broad range of substrates

• very good and consistent ink transfer with excellent area coverage

• high solid density and minimum dot gain in the halftones

• intermediate depths with excellent contour definition Efficient handling and superior durability

When selecting plate materials, it is important to consider the specific requirements of the printing job, including the type of printing process, the printing substrate and the quality and quantity requirements of the final output. For marketing materials such as brochures, leaflets and promotional posters, the choice of print material will have a direct impact on the visual appeal and effectiveness of the printed material. Factors such as colour vibrancy, image clarity and overall print quality are critical to conveying a compelling message and attracting the attention of the target audience.

In short, the choice of plate material can have a significant impact on the quality, cost and environmental impact of the printing process. While conventional metal plates remain a popular choice for many commercial plate applications, alternative materials such as plastics, photopolymers and digital plates offer viable options with unique advantages. In addition, unconventional materials can provide creative opportunities for artistic and experimental printing projects. By understanding the properties and suitability of different plates, businesses and designers can make informed decisions to achieve the desired results from the materials they market.

Post time: Jul-15-2024