Wire binding is a common method used by everyone when binding documents, reports and speeches. Professional and polished, wire binding is the preferred choice for businesses, organisations and people in their daily lives. Round stitching is a crucial part of wire binding. Let's take a look at the different types of wire binding and the importance of round stitching in the process.

Wire binding, also known as double ring binding, is a versatile and durable method of binding that can provide a sleek, modern look to any form of document, and there are many types of coil binding, each with unique features and benefits. The most common types of wire binding include double loop wire binding, spiral wire binding and plastic wire binding.

Regardless of the type of binding used, the quality of the round stitching is critical to the overall effectiveness of the binding process, and ring stitching is specifically designed for wire binding applications and plays an important role in ensuring the durability and longevity of the bound documents.

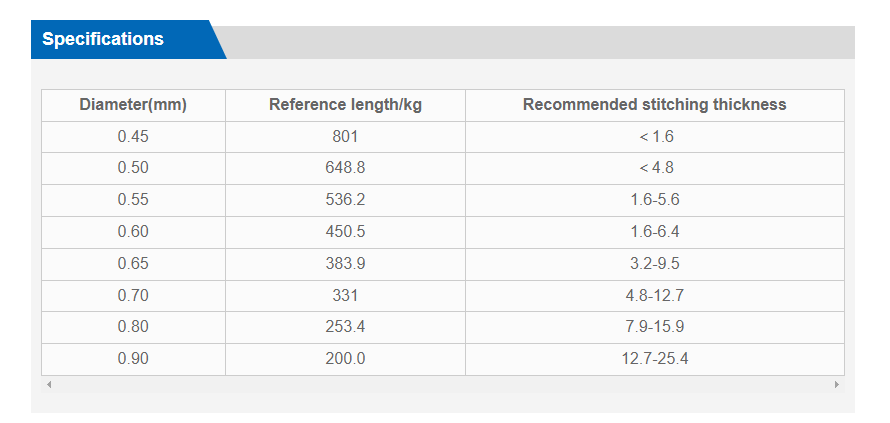

Our company produces round stitching threads, such as this one,

LQ-RSW Round Stitching Wire for binding books and periodicals

LQ Round stitching wire used to bind books and periodicals, it is the final stage of books and periodicals processing.

Tensile strength: 650-850N/mm2

Tolerance: 0.05mm

Double loop wire binding, also known as double loop wire binding, is popular for its professional appearance and durability. This method of binding involves bending metal wires into a double loop pattern, providing a secure, tamper-proof binding solution. This type of binding is better suited to documents that need to lay flat when opened, making it a practical choice for speeches and reports.

Secondly, spiral binding uses continuous coils that pass through small, closely spaced holes in the edges of the document. This type of binding allows for easy page turning and is suitable for documents that need to be updated or new content added frequently, such as manuals and reference materials.

Then there's plastic wire binding, also known as comb binding, which uses multiple comb fingers on top of a plastic spine to hold the pages in place by opening and closing them. This type of binding has a more professional finish and makes it easier to edit or add and remove pages.

Round stitching is available in a variety of diameters and colours and can be customised and personalised to suit specific binding requirements. Its smooth, consistent surface ensures a seamless binding process, giving documents a professional look. In addition, round stitching is made from high-quality materials that are durable and resistant to bending or warping. This durability ensures that bound documents remain intact and can preserve important information for a long time.

All in all, wire binding is a popular and effective way to produce professional-looking documents, and the type of wire binding used can greatly affect the overall appearance and functionality of the bound material. Round stitching plays a very important role in the wire binding process, offering durability, functionality and finish. If you have any need for round stitching, please contact us in time, our company has been exporting related consumables to all over the world for many years with a wide range of products, if you are interested, you can click on our website to contact us.

Post time: Jun-24-2024