In offset printing, the offset blanket plays a vital role in ensuring high quality prints. The thickness of the offset blanket is one of the key factors that determine its performance. In this article, we will take a closer look at the importance of offset blanket thickness and how it affects overall print quality.

Offset printing blanket is an important part of the offset printing process, between the printing plate and the substrate plays an intermediary role. The role of the blanket is to transfer ink from the printing plate to the substrate to ensure the accuracy and consistency of image reproduction. Offset printing blanket thickness plays a vital role in determining the quality of the print.

So, what is the thickness of the offset blanket? The thickness of an offset blanket is usually measured in millimeters (mm) or micrometers (µm). The standard thickness of offset blankets ranges from 1.95 mm to 2.20 mm, with a variety of thicknesses available to meet specific printing needs. The thickness of an offset blanket directly affects its ability to adhere to the surface of the plate and substrate, which in turn affects ink transfer and overall print quality.

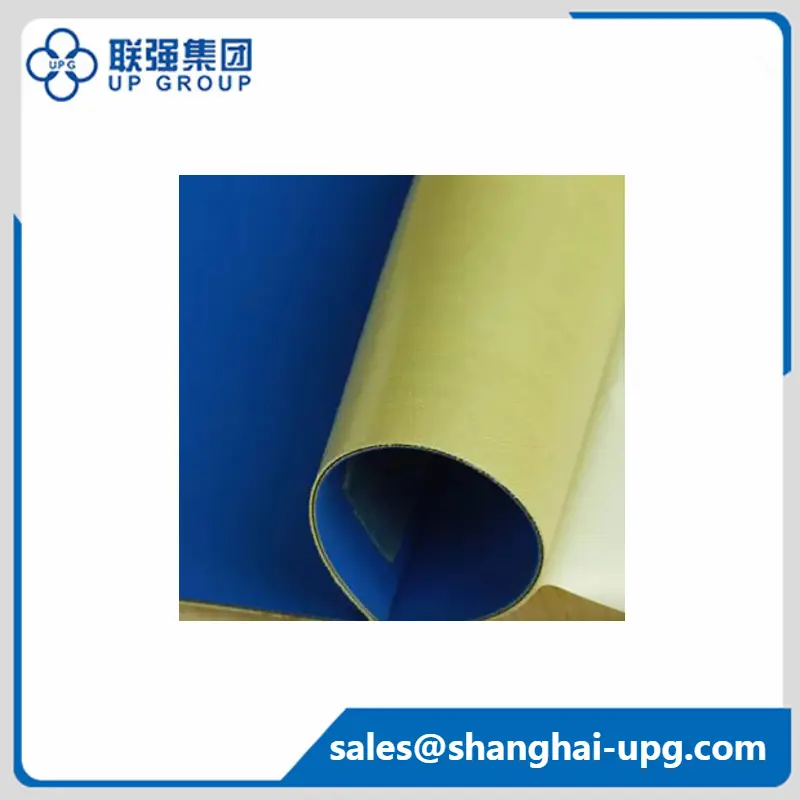

Our company also produces Offset Blankets, such as this one LQ-AB Adhesion Blanket For Offset Printing.

LQ Self-adhesive blankets is appropriate to business form printing. It is easy for cutting and stripping. Paper edge trace is few, easy to remove and replace, spot inking and dot reappearance performance is particularly good.

Offset blanket thickness is an important consideration for printers and print buyers. A thicker blanket provides better support and cushioning, which is critical to achieving consistent ink transfer and maintaining image fidelity. Additionally, thicker blankets can help compensate for minor defects in the plate or substrate, thereby improving print quality.

Conversely, thinner offset blankets may be suitable for specific printing applications that require lower press forces. It is important to note, however, that thinner blankets are more susceptible to wear and tear, which affects their longevity and overall performance.

Offset blanket thickness not only affects ink transfer and image reproduction, but also affects print quality. It also affects the entire printing process, including dot gain, color consistency and printing register and other factors. Correct selection and maintenance of the appropriate thickness of the offset blanket helps to obtain clearer, more vivid prints, while minimizing color and register variations.

In the competitive landscape of churn printing, print quality is a key differentiator for print providers from their competitors. By understanding the importance of offset blanket thickness and its impact on print quality, print suppliers can make informed decisions when selecting the right offset blanket for their specific printing needs.

When evaluating offset blankets, it is important to consider the specific requirements of the printing job, including the substrate, ink and type of press. Different printing applications will require different thicknesses of blankets for best results. For example, when printing on rough or textured substrates, a slightly thicker blanket may be required to ensure consistent ink coverage and image clarity.

In addition, advances in offset blanket technology have also led to the development of specialized blankets to address specific printing challenges, for example, compressible offset blankets can provide greater compressibility, resulting in improved ink transfer and print quality, especially on uneven or challenging substrates.

In the selection of offset blankets, in addition to thickness, should also consider the compressibility of the blanket, surface texture and durability, and other factors, a comprehensive understanding of these factors to help print providers to make informed decisions in line with their production requirements and quality standards.

In short, the thickness of the offset blanket is a key factor that seriously affects the quality of offset printing. Print providers and print buyers should carefully consider the specific requirements of their print jobs and select the appropriate thickness of offset blankets to get the best results. By understanding the impact of offset blanket thickness on print quality, print providers can improve their print output and deliver superior results that meet the highest standards of quality and consistency.

Post time: Jul-23-2024