LQ-UV LASER CODING PRINTER

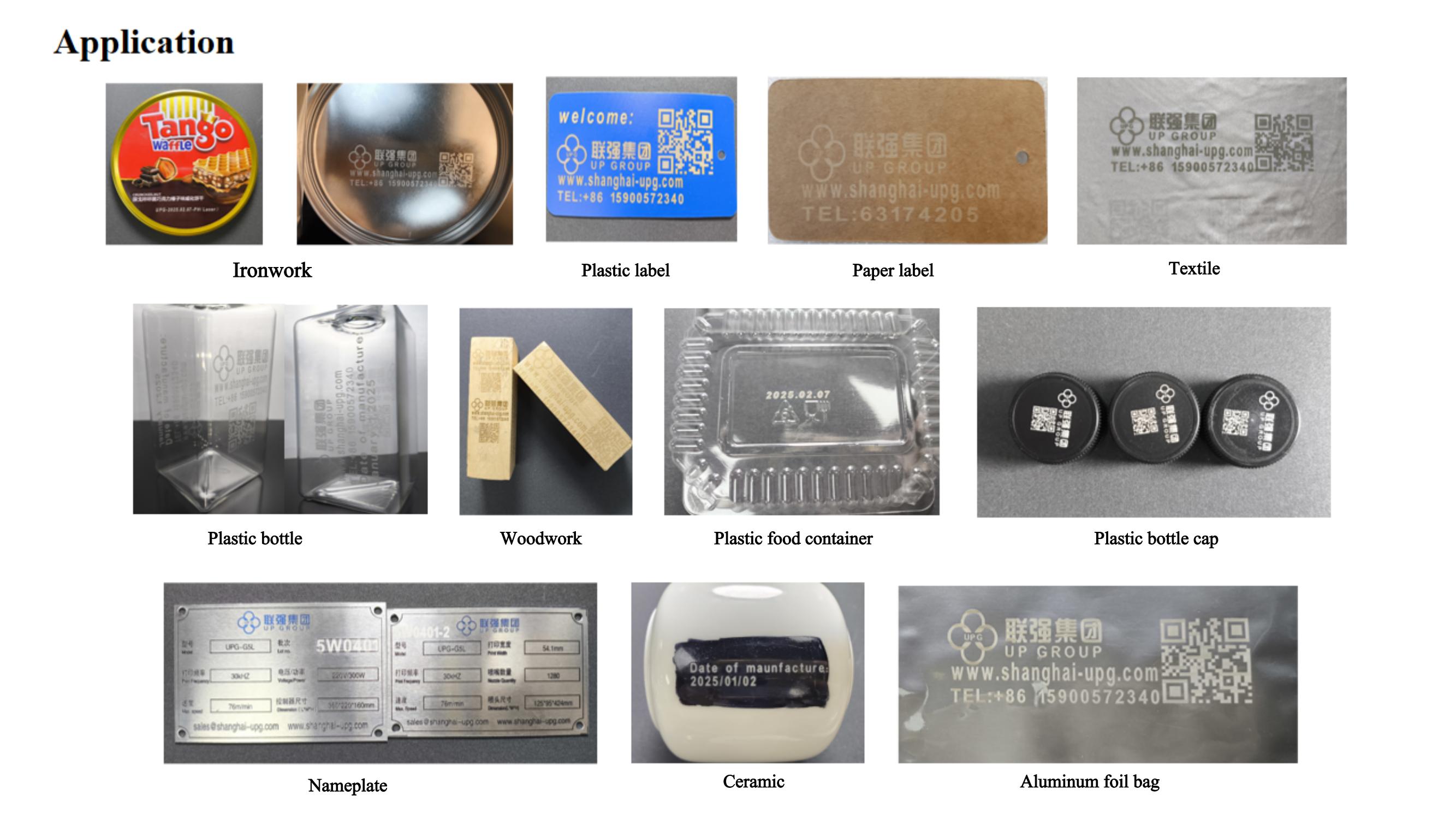

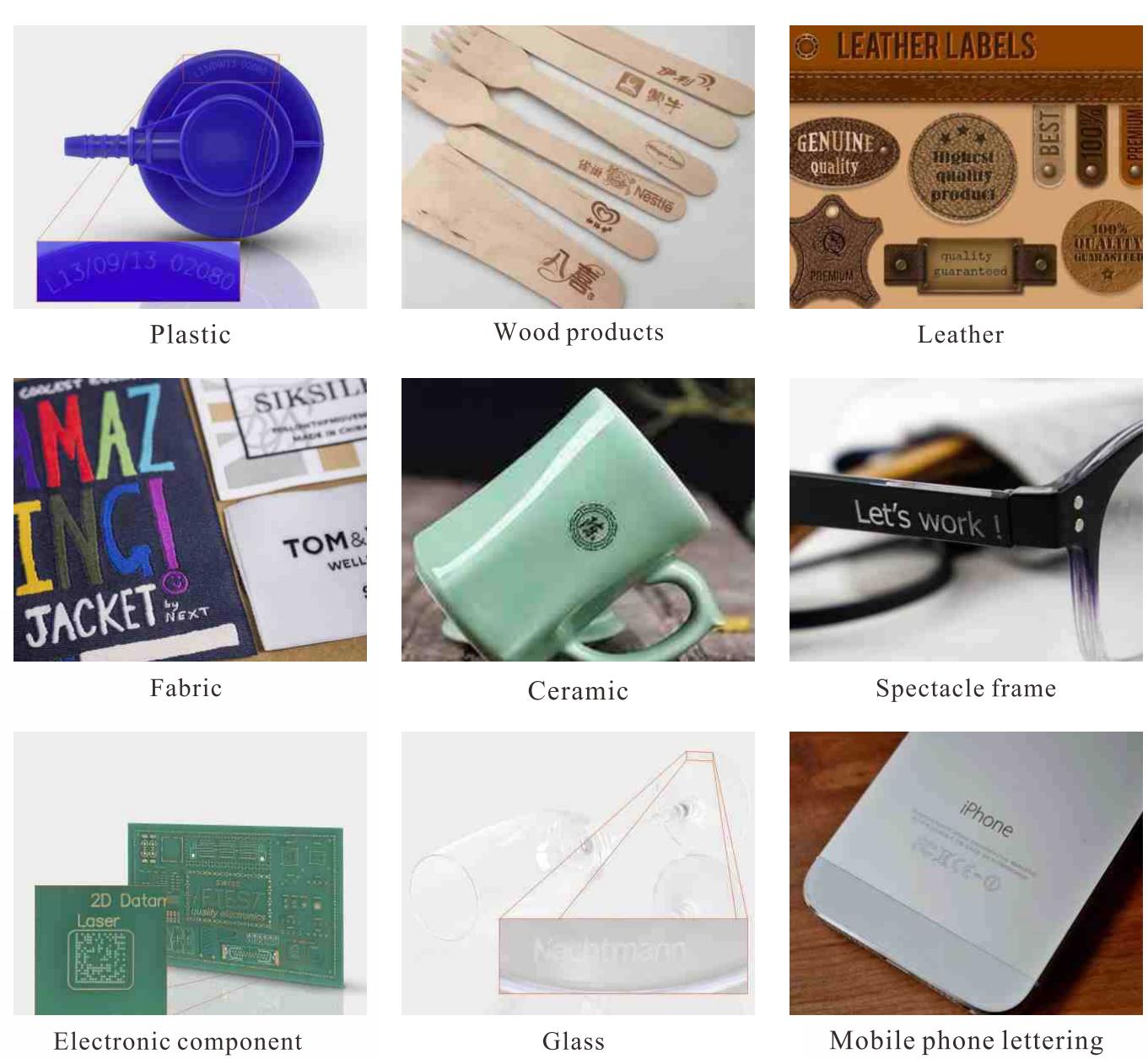

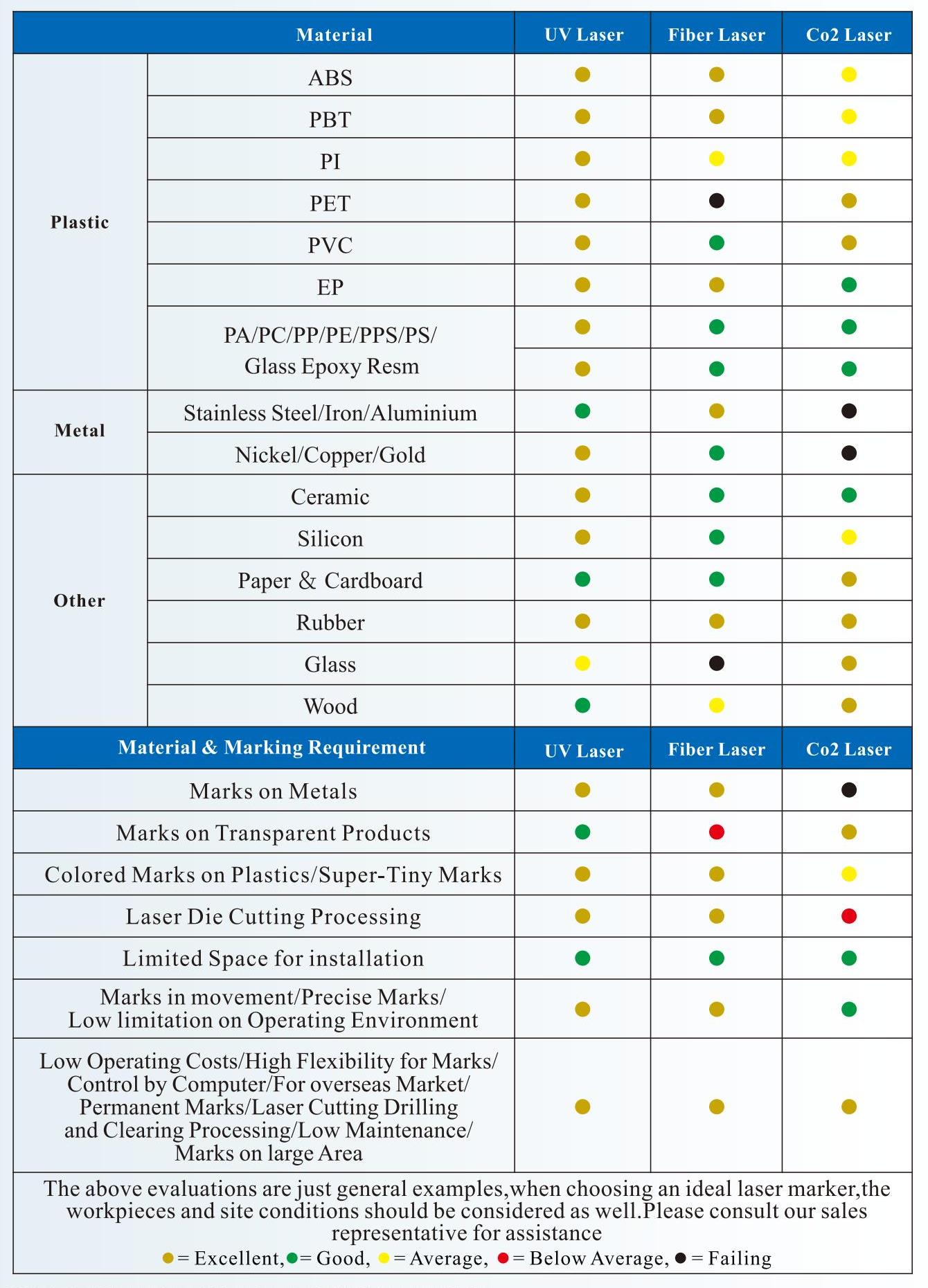

Applicable materials

Glass: The surface and interior carving of glass and crystal products.

Widely used for surface engraving of metals, plastics, wood, leather, acrylic, nanomaterials, fabrics, ceramics purple sand and coated flms. (Actual testing is required due to different ingredients)

Industry: Mobile phone screens, LCD screens, optical components, hardware, glasses and watches, gifts, PC, precision electronics, instruments, PCB boards and control panels, inscription display boards, etc. Adapt to surface treatment such as marking, engraving, etc, for high flame retardant materials

Technical Data Sheet

Our high-speed laser printing system, using integrated, modular design, standardized manufacturing, set miniaturization, high flexibility, high speed, user-friendly operation in one, greatly enhance the comprehensive ability of products.

Movable flying inkjet printer, novel appearance, unique structure, convenient operation interface, high modulation frequency, fast coding speed, high precision, stable performance, powerful functionality, independent research and development, can be customised according to customer needs, modification, increase, decrease the function and so on.

Technological Advantages

With the development of laser inkjet technology, more and more manufacturers are using laser inkjet on their products. Uv laser inkjet machine with its unique low-power laser beam, suitable for the highend market of ultra-fine processing, cosmetics, drugs, food and other polymer materials packaging bottle surface marking, fine effect, clear and firm marking, better than ink inkjet and pollution-free

Communication function

Data communication via USB interface and code sending software

Multi-material inkjet

LCD glass two-dimensional code, glass surface punching, metal surface coating marking, plastic keys, electronic components, gifts, communication equipment, building materials, etc.

Red light location

With a red light positioning assist system, this feature can help the operator quickly find the inkjet position when changing the inkjet product.

Power-off protection

Industry-leading data protection technology ensures that data is not lost during emergency power outages or unplanned shutdowns, helping operators operate quickly.

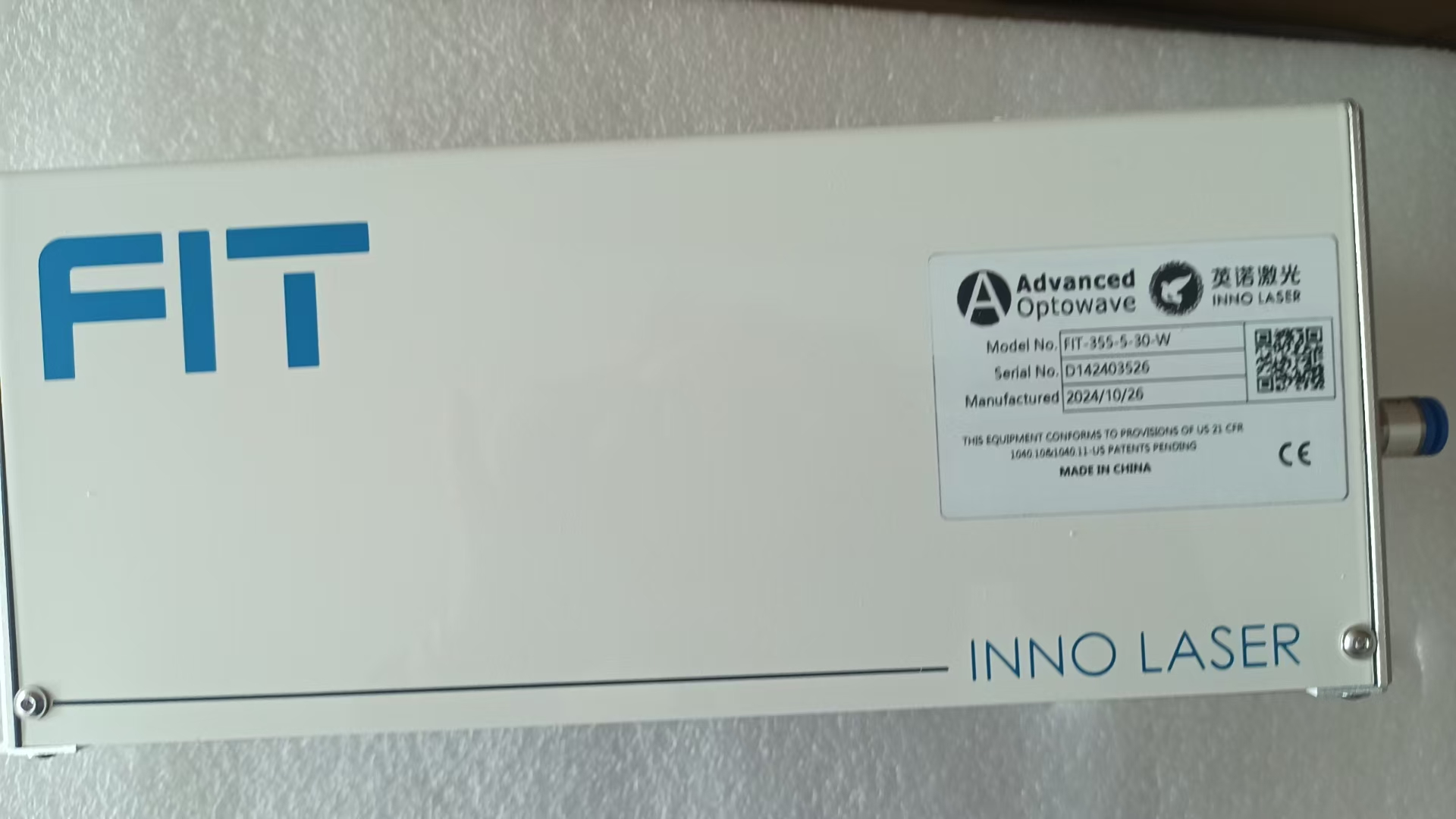

INNO LASER

INNO LASER technology advantages and market position

INNO LASER is one of the few industrial laser manufacturers in the world with the core technology and production capacity of nanosecond, subnanosecond, picosecond and femtosecond micromachining lasers.

The company’s laser products cover different bands from infrared to deep ultraviolet, and a variety of pulse widths from nanoseconds to femtoseconds, which are recognized by the global market and have international competitiveness.

Ultraviolet laser is one of the core components of lithography machine, especially in EUV (extreme ultraviolet light) lithography machine, the role of ultraviolet laser is very important.

The importance of ultraviolet laser in lithography machine

The role of the light source: the ultraviolet laser as the light source of the lithography machine, emits a specific wavelength of ultraviolet light, and forms a high-energy spot after the optical system is focused to achieve the transfer of the circuit pattern. The choice and design of the light source have an important influence on the resolution and machining accuracy of the lithography machine.

Role in EUV lithography: In EUV lithography, the ultraviolet laser is the key to producing extreme ultraviolet light, which is essential for the production of chips with processes of 5nm and below. The power and stability of EUV light source directly affect the production efficiency and chip quality of the lithography machine. Uv laser is not only the core component of the lithography machine, but also plays a crucial role in the EUV lithography machine.

Applicable materials

Glass: The surface and interior carving of glass and crystal products.

Widely used for surface engraving of metals, plastics, wood, leather, acrylic, nanomaterials, fabrics, ceramics purple sand and coated flms. (Actual testing is required due to different ingredients)

Industry: Mobile phone screens, LCD screens, optical components, hardware, glasses and watches, gifts, PC, precision electronics, instruments, PCB boards and control panels, inscription display boards, etc. Adapt to surface treatment such as marking, engraving, etc, for high flame retardant materials

|

Applicable Industry |

Electronic products, wire and cable and pipe, food and beverage, daily chemical supplies, pharmaceutical and other industries |

|

|

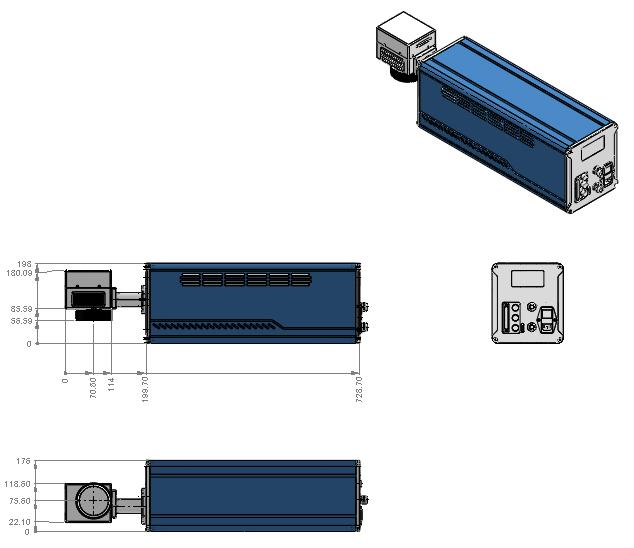

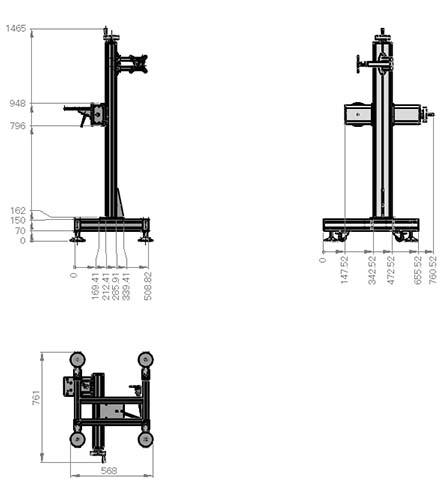

Laser machine complete characteristics

|

Laser output power |

3/5/10/15/20W |

|

Material of complete machine |

Alumina and sheet metal construction |

|

|

Laser |

Ultraviolet laser generator |

|

|

Laser wavelength |

355nm |

|

|

Control motherboard |

Industrial grade highly integrated integrated motherboard |

|

|

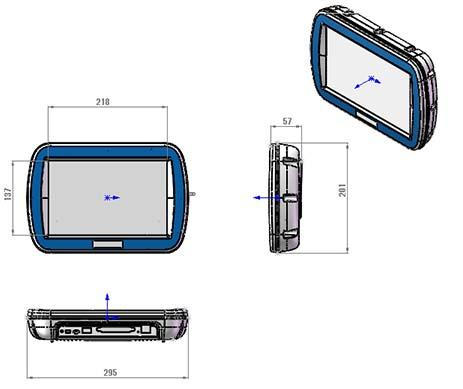

Operating platform |

10 inch touch screen |

|

|

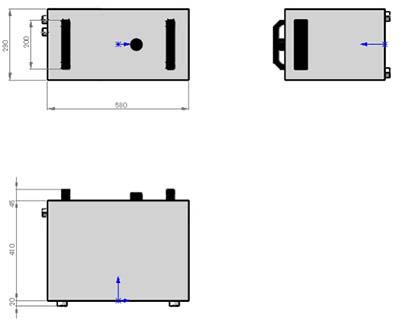

Cooling system |

Water cooling (working temperature 25℃) |

|

|

port |

SD card interface /USB2.0 interface/communication interface |

|

|

Data protection |

Ensure that user data is not lost in case of unexpected power failure |

|

|

Lens rotation |

The scanning head can be rotated 360 degrees at any Angle |

|

|

Power requirements |

AC220V,50-60Hz |

|

|

Overall power |

1200w |

|

|

Machine weight |

90kg |

|

|

Pollution level |

The marking itself does not produce any chemicals |

|

|

Environmental resistance |

Storage ambient temperature |

-10℃-45℃ (without freezing)

|

|

Operating ambient temperature |

||

|

Storage humidity |

10%-85% (no condensation) |

|

|

Working ambient humidity |

||

|

Parameter of Lens

|

Marking range |

Standard 110*110mm |

|

Marking line type |

Lattice, vector |

|

|

Minimum line width |

The 0.01 mm |

|

|

Repeated positioning accuracy |

The 0.01 mm |

|

|

Positioning mode |

Red light location |

|

|

Focusing mode |

Double red focus |

|

|

Number of marking character lines |

Edit at will within the marking range |

|

|

Line speed |

0-280m/min (depending on product material and marking content) |

|

|

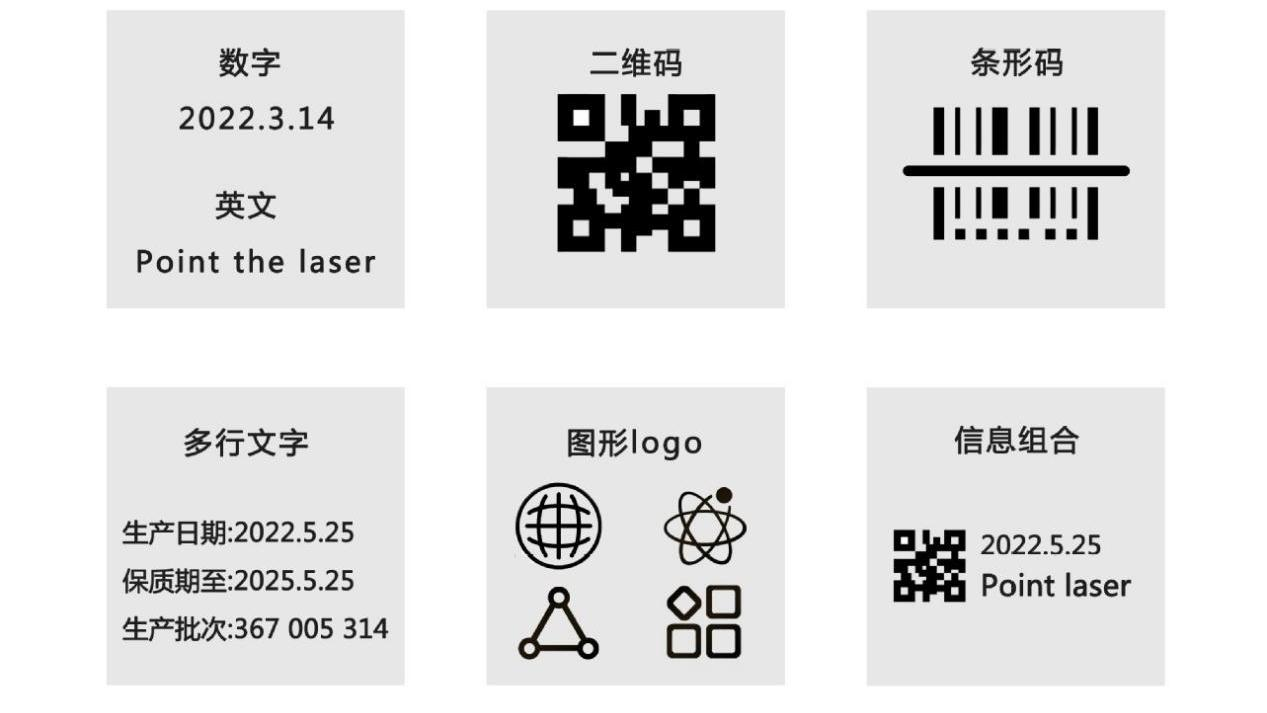

Character type

|

Support font types |

Single line font, Double line font, and dot matrix font |

|

Graphics file format |

PLT format vector file input/output |

|

|

File format |

BMP/DXF/JPEG/PLT |

|

|

Graphic element |

Point, line, arc text, rectangle, circle |

|

|

Variable text |

Serial number, time, date, counter, shift |

|

|

Bar code |

Code39、Code93、Code128、EAN-13 etc |

|

|

Two-dimensional code |

QRCode、Data Matrix etc

|

|