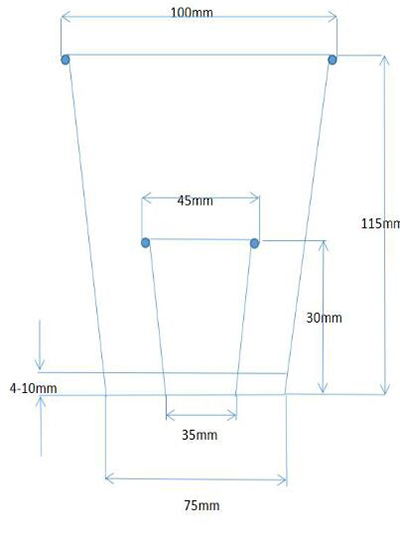

LQ-S100 paper cup machine

PLANE GRAPH

Technical Data

| Model | High Speed Simple Model Ultrasonic Paper Cup Machine YB-S100 |

| Paper Cup Size | 2 -12 OZ (Mould exchangeable, Max Cup Height: 115mm, Max Bottom width: 75mm) |

| Rated Speed | 100-110pcs / min ( Speed affected by cup size , paper quality thickness ) |

| Raw Material | One or Two side PE coated Paper ( Popular for Hot and Cold drink Cups ) |

| Suitable paper weight |

150-350gsm |

| Paper Source | 50/60HZ,380V/220V |

| Total Power | 5KW |

| Total Weight | 2500KG |

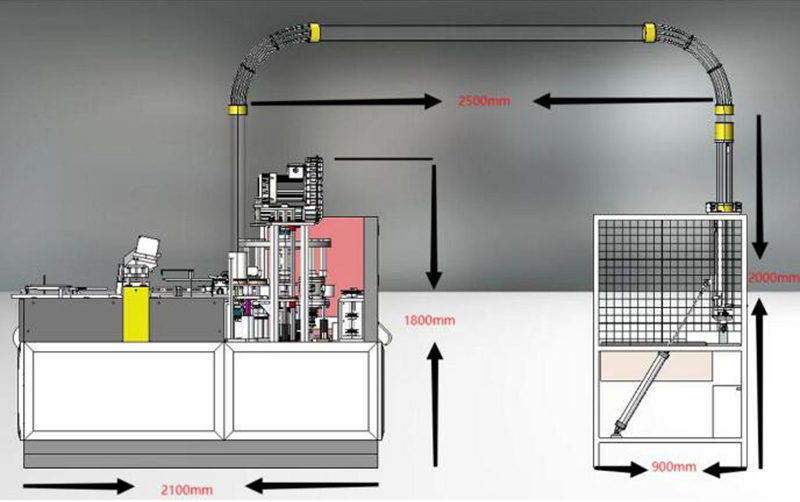

| Pacl Size(L*W*H) | 2200*1350*1900mm (machine size) 900*700*2100mm ( collecting table size) |

| Cup side Welding | Ultrasonic heater |

Machine Size

Control Panel

Control panel with good quality switches , temperature controller and speedconverter.

All the operation of machine can be finished easily by this panel

Electric System

Quality Brand electric System like Delta . Schneider

Main electrical equipment configuration

| Touch screen | 1 | Delta |

| Inverter | 1 | Delta |

| Step driver | 1 | Shenzhen Xinghuo |

| Temperature module | 1 | WK8H |

| PLC | 1 | Delta |

| Ultrasonic | 1 | Kejian |

| Switching Mode Power Supply | 1 | Mingwei |

| Solid state relay | 6 | Yangming |

| Air switch | 5 | CHNT |

| AC contactor | 4 | Schneider |

| Photoelectric switch | 8 | Sick/Panasonic |

| Miniature relay | 6 | OMRON |

| Encoder | 1 | OMRON |

| PLC DC amplifier board | 1 | OMRON |

| Phase sequence protector | 1 | CHNT |

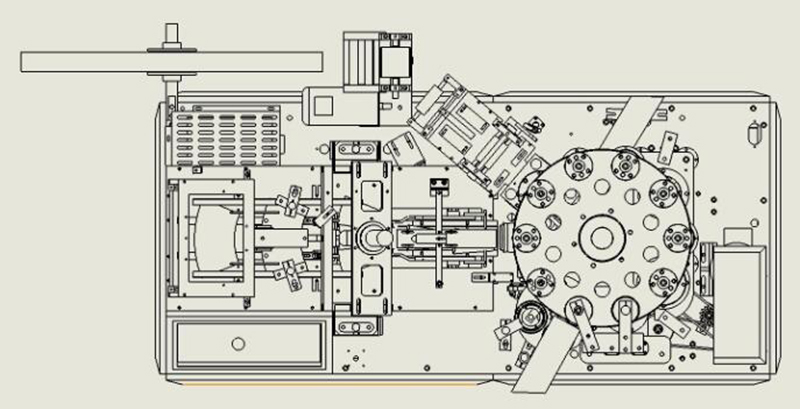

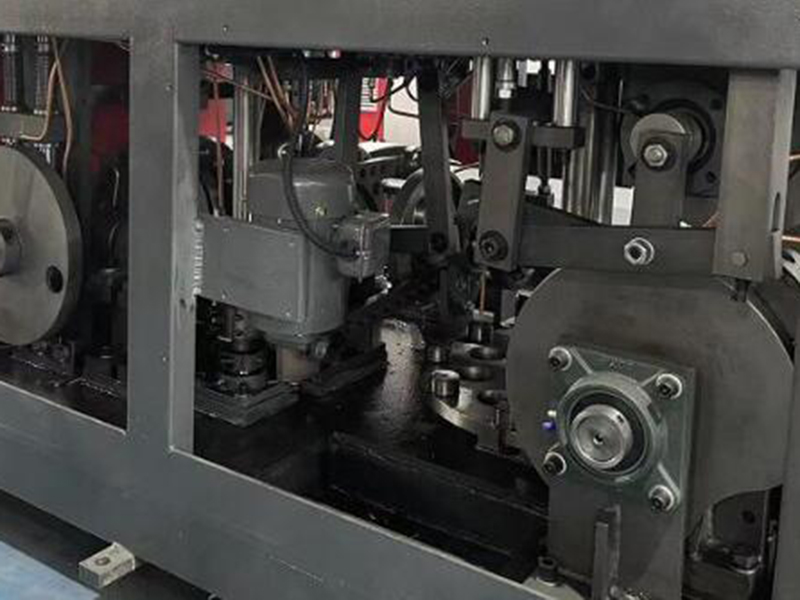

Main Turn plate

This model is equipped with 10 Cup molds, which operates faster than the old 8 Cup molds

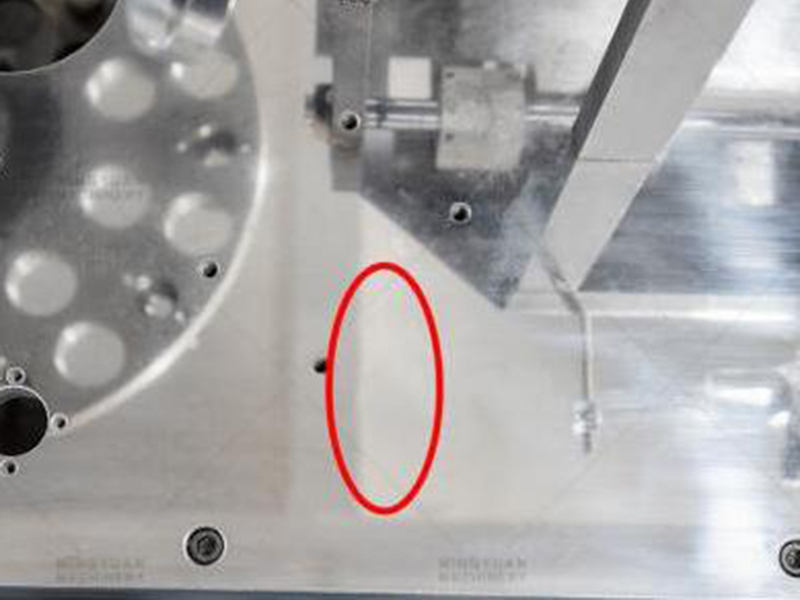

Bottom Heater System

The new design adds a bottom heating system more than the old design which make the paper cup sealing effect is more better.

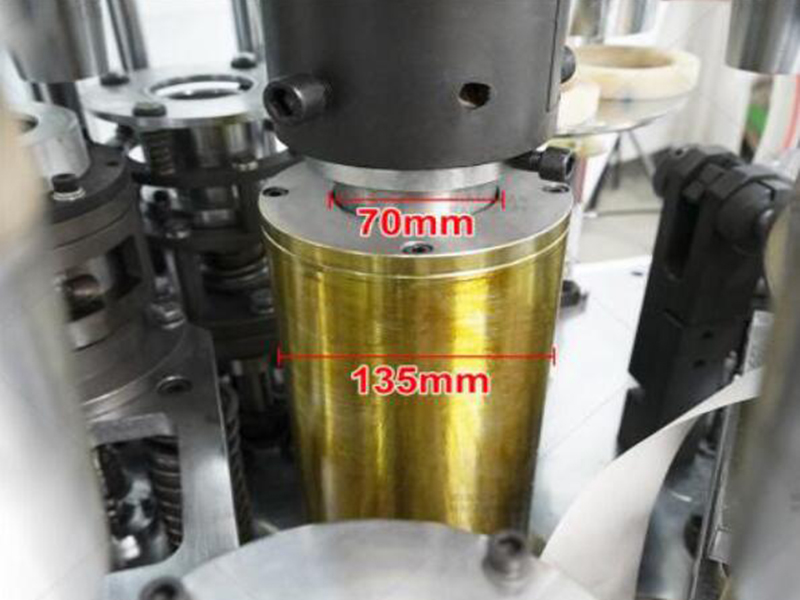

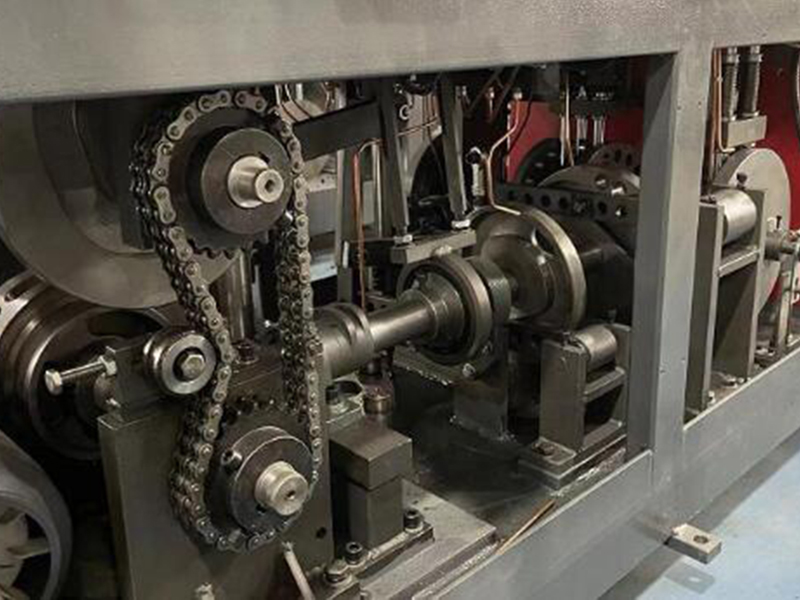

Principal axis

Large and thick central shaft makes machine run stably at high speed without shaking

Bottom Paper Feeding Unit

New design : The steel plate presses the bottom paper to make the paper feeding more stably and smoothly

Moving Cooling fan

Two cooling fans, two fans can make the paper fan cooling faster, make the cup fan better sealing

Cam drive and automatic lubrication system

The whole machine adopts automatic oil lubrication system( oil circulation system is including oil motor,filter, copper pipe )which makes all gear moving parts working at high speed much more smoothly and greatly Improve the service life of spare parts

Machine integrated motherboard

Integrated steel board: The operation board is large and thick integrated steel board, more

durable and easy to clean

Delivery parts list:

Product name and quantity

| One copper head electric heating rod |

One 10 inch sliding wrench |

Three small springs |

Heating and preheating one main hot ring each |

Two heating pipes |

| Bearing 5204 + knurled wheel one set |

One set of Allen wrench |

One set of external hexagon wrench 8-10 12-14 17-19 22-24 |

Six foot screws M18 |

One oil bottles |

| One Measuring pencil |

One cross screwdriver |

One Hammer | One machine wrench |

One pieces of adhesive tape |

| Ring wrench 12-14, 17-19, 1 each |

One pliers | Three skin aspirating (transparent) |

Eight socket head screws, 6, 8, 10 and 12 |

Twelve nut flat pad |

Factory introduction