LQ – Fiber laser marking machine

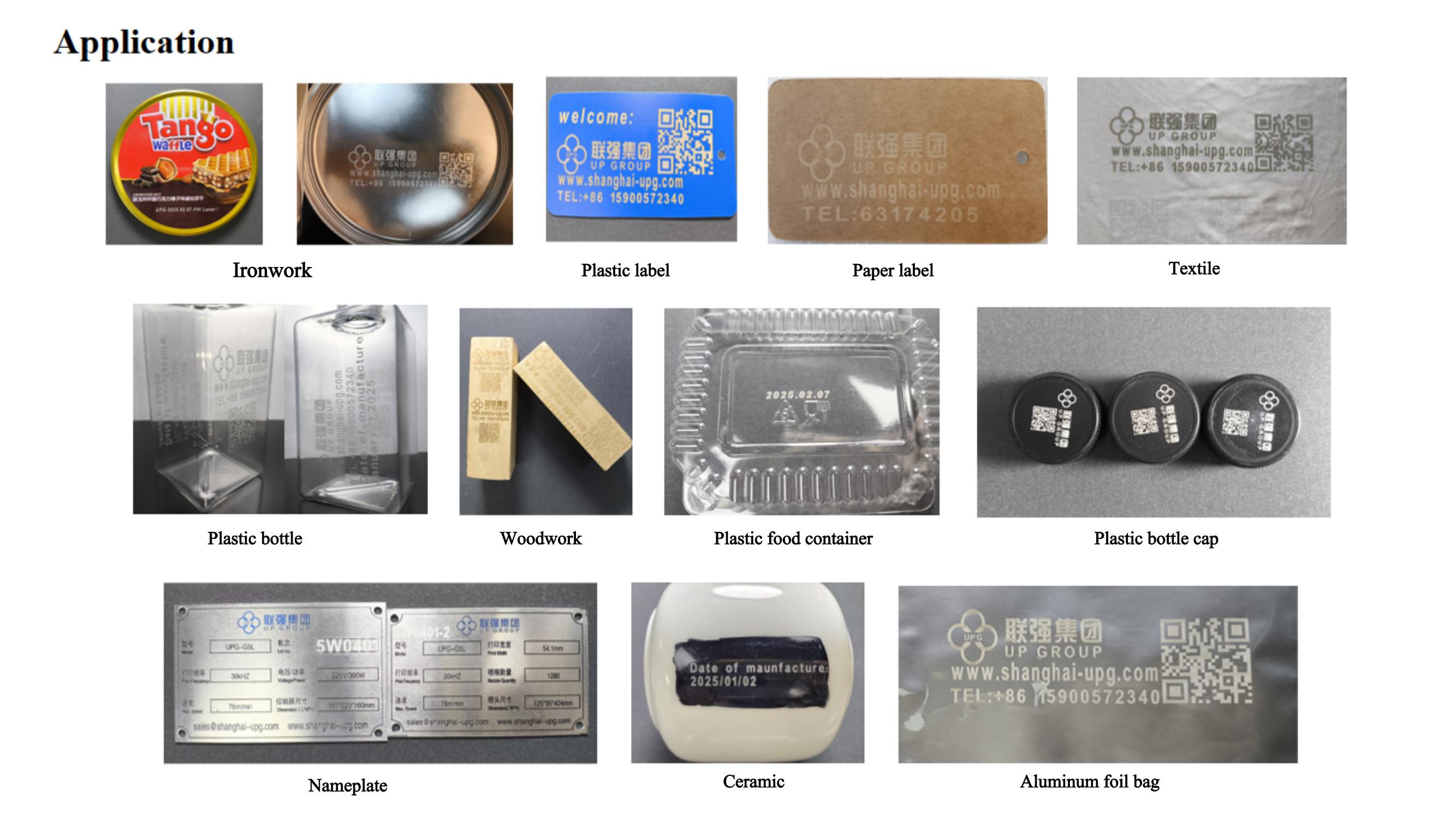

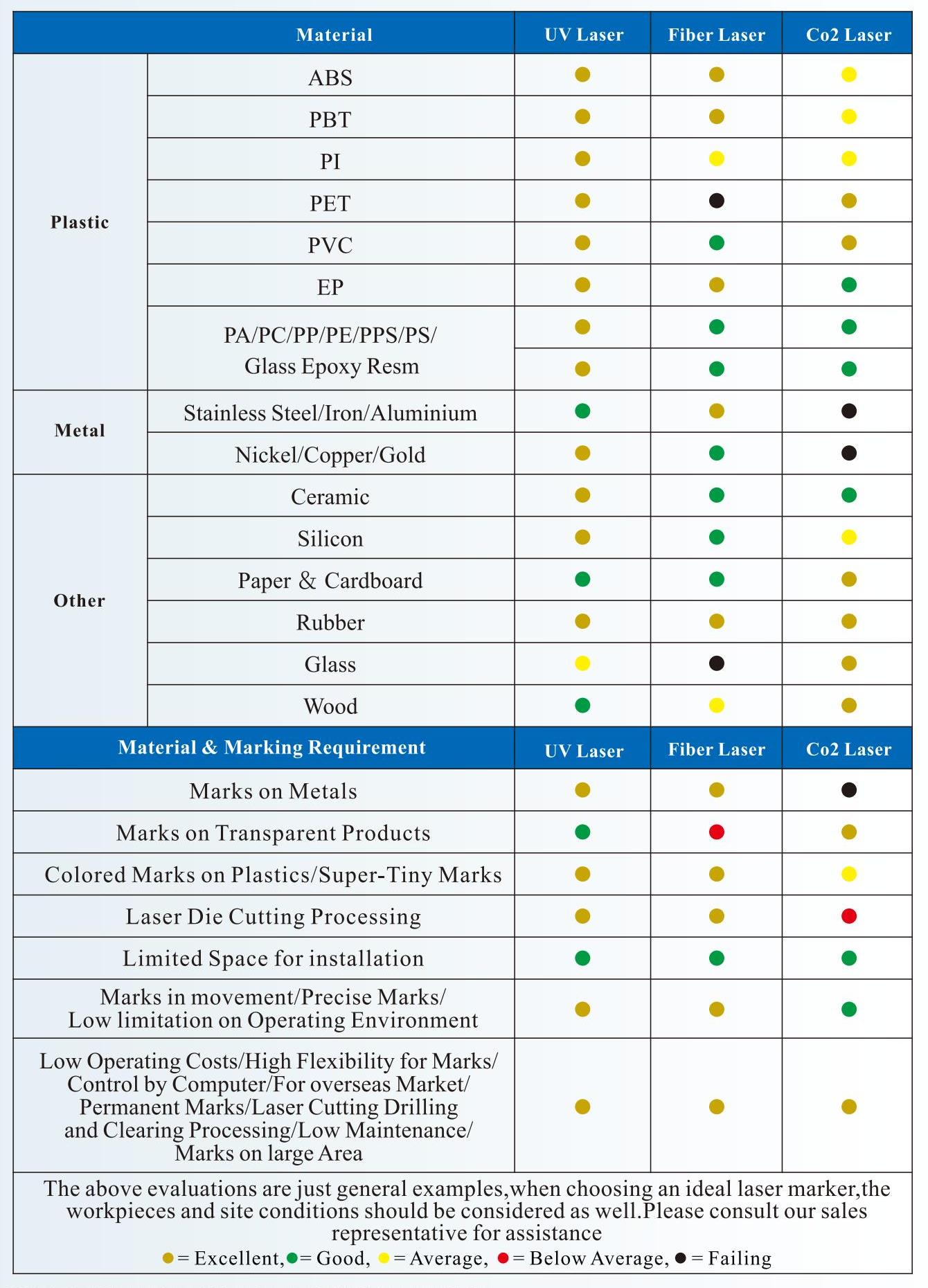

The LQ Fiber Laser Marking Machine is a high-precision tool designed for marking, engraving, and etching various materials, including metals, plastics, ceramics, and more. Utilizing advanced fiber laser technology, it produces clear, permanent, and high-quality marks with exceptional speed and accuracy. The fiber laser has a long operational life, minimal maintenance, and high efficiency in converting electrical energy into laser energy, making it an energy-saving solution.

This machine is widely used in industries such as electronics, automotive, aerospace, and manufacturing for engraving serial numbers, bar codes, logos, and other intricate designs. Its non-contact marking process ensures that the integrity of the material is preserved without any damage, making it ideal for delicate or high-value items. Additionally, the LQ Fiber Laser Marking Machine offers flexibility with various wavelengths and power levels to meet different marking needs.

It is user-friendly, compatible with most design software, and supports easy customization of settings for different applications. Its robust construction ensures durability, even in demanding industrial environments.

| Technical Parameters: |

| Laser power: 20W-50W |

| Marking speed: 7000-12000mm/s |

| Marking range: 70*70,150*150,200*200,300*300mm |

| Repetitive accuracy: +0.001mm |

| Focused light spot diameter: <0.01mm |

| Laser wavelength: 1064mm |

| Beam quality: M2<1.5 |

| Laser output power: 10%~100% continuously adjustable |

| Cooling method: Air cooling |

Applicable materials

Metals: Stainless steel, carbon steel, aluminum oxide, aluminum alloy, aluminum, copper, iron, gold, silver, hard alloy and other metal materials can all be surface engraved.

Plastics: Hard plastics, PVC materials, etc. (Actual testing is required due to different compositions)

Industry: Nameplates, metal/plastic accessories, hardware, jewelry, metal spray painted plastic surfaces, glazed ceramics, purple clay pots, painted paper boxes, melamine boards, mirror paint layers, graphene, chip lettering removal can, milk powder bucket. etc.