LQ-Creasing Matrix

PVC Creasing Matrix

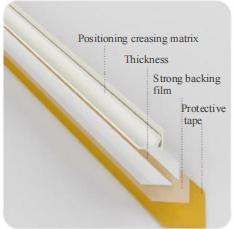

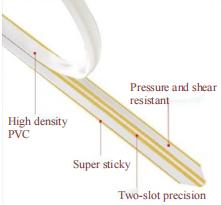

PVC Creasing Matrix is an auxiliary tool for paper indentation, it is mainly composed of strip metal plate and different specifications of indentation lines. These lines have a variety of widths and depths, suitable for different thicknesses of paper, to meet the needs of various folding designs. PVC Creasing Matrix is designed with the needs of users in mind, some products are equipped with accurate scale, convenient for users to make accurate measurements when making complex folding.

Applicable models:

Flat pressing machine/Automatic die cutting machine

Applications:

White cardboard/ copper paper/ grey cardboard various cardboard / PVC sheet/ corrugated paper/ color box/ gift box various packaging, etc

Advantages :

- Withstand voltage times: Withstand voltage than similar 10%.

- Easy to use: Simplify folding process, improve production efficiency.

- Effect: Clear indentation, to ensure the accuracy of folding.

- Reusable: It has good durability and stability, can be used many times and maintain the same performance.

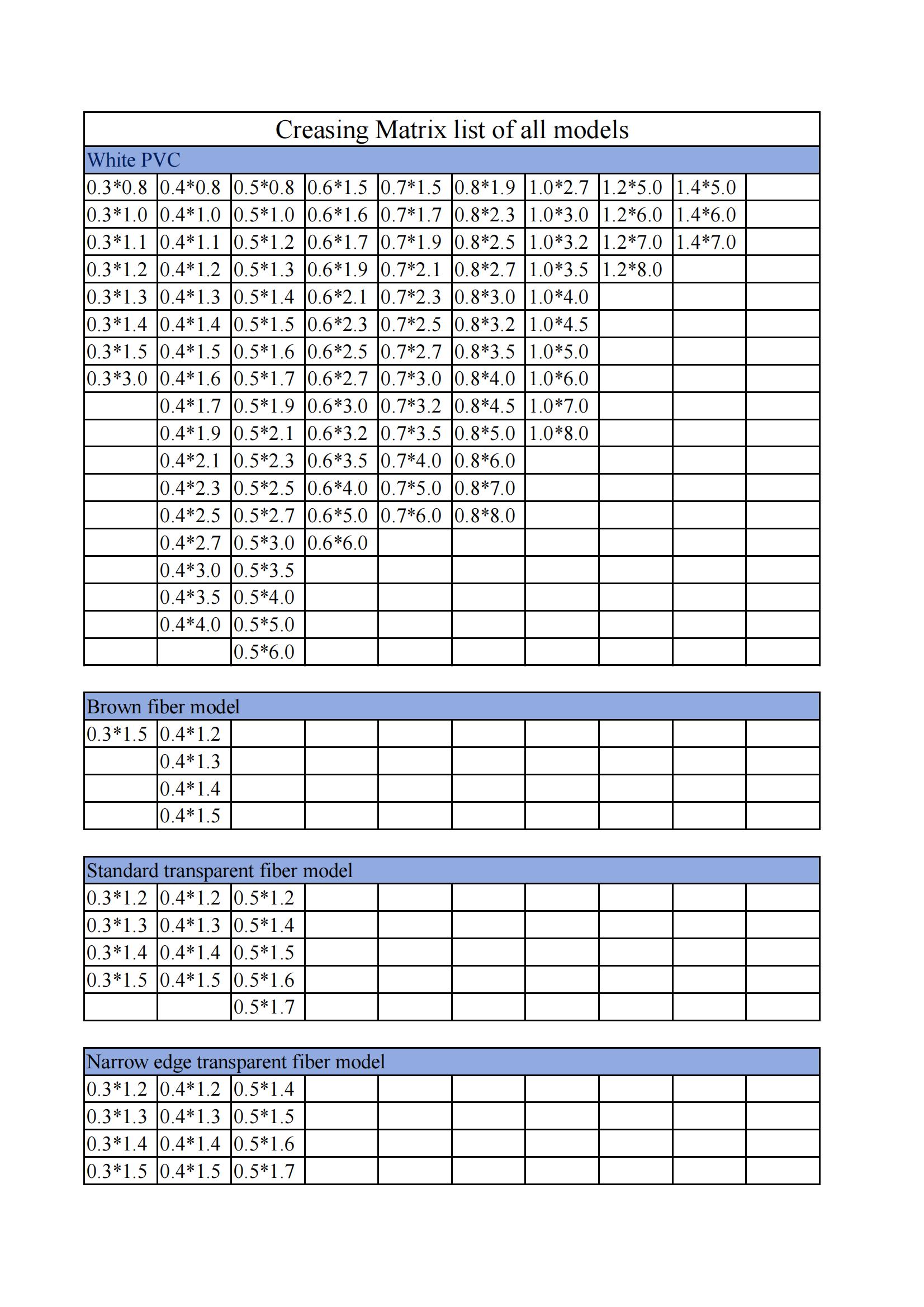

Parameter

| Cardboard selection (according to die cutting machine height 23.77mm to do the standard) | ||||

| Paper gsm(mm) | Thickness gsm (mm) | Cutting rule height (mm) | Cutting rule height (mm) | Type |

| 小于 100 克 | 0.1 | 23.5 | 1.5pt/0.53mm | 2PT1.2-1.4(0.3×0.6) |

| 150-190 | 0.15-0.25 | 23.5 | 2pt/0.71mm | 2PT1.2-1.4(0.3×0.6) |

| 200-220 | 0.26-0.34 | 23.5 | 2pt/0.71mm | 2PT1.2-1.4(0.3×0.6) |

| 230-280 | 0.35-0.40 | 23.4 | 2pt/0.71mm | 2PT1.2-1.4(0.3×0.6) |

| 290-330 | 0.42-0.47 | 23.4 | 2pt/0.71mm | 2PT1.2-1.4(0.3×0.6) |

| 350-400 | 0.50-0.56 | 23.3 | 2pt/0.71mm | 2PT1.2-1.4(0.3×0.6) |

| 410-450 | 0.57-0.63 | 23.2 | 2pt/0.71mm | 2PT1.5-1.9(0.3×0.6) |

| 460-500 | 0.64-0.70 | 23.1 | 3pt/1.05mm | 2PT1.9-2.3(0.3×0.6) |

| 520-600 | 0.72-0.84 | 22.9 | 4pt/1.42mm | 3PT1.9-2.3(0.3×0.6) |

| 620-700 | 0.84-0.98 | 22.8 | 4pt/1.42mm | 3PT2.3-2.7(0.3×0.8) |

| Corrugated paper selection (according to the die cutting cutter height of 23.77mm) | ||||

| Paper | Thickness gsm (mm) | Cutting rule height (mm) | Cutting rule height (mm) | Type |

| E pit | 0.46-0.50 | 23.2 | 2pt/0.71mm | 3PT2.7-3.2(0.3×0.9) |

| E pit | 0.60-0.69 | 23 1 | 3pt/1.05mm | 4PT2.7-3.2(0.3×0.9) |

| E pit | 0.70-0.80 | 23.0 | 4pt/1.42mm | 4PT3.2-3.5(0.3×0.9) |

| B pit | 0.81-0.89 | 22.9 | 4pt/1.42mm | 4PT3.5-4.0(0.3×0.9) |

| B pit | 0.90-0.96 | 22.8 | 4pt/1.42mm | 4PT4.0-4.5(0.3×0.9) |

| A pit | 4.0-4.5 | 22.7 | 4pt/1.42mm | 4PT2.7-3.2(1.0×7.0) |

| B pit | 2.5-3.0 | 22.6 | 4pt/1.42mm | 4PT3.5-4.0(1.0×7.0) |

| C pit | 3.5-4.0 | 22.5 | 4pt/1.42mm | 4PT3.5-4.0(1.0×5.0) |

| E pit | 1.5-2.0 | 22.4 | 4pt/1.42mm | 3PT2.3-2.7(1.0×5.0) |

| F pit | 0.8-1.0 | 22.3 | 3pt/1.05mm | 2PT1.9-2.3(0.8×2.3) |