LQ-CB-CTP PLATE PROCESSOR

FEATURE

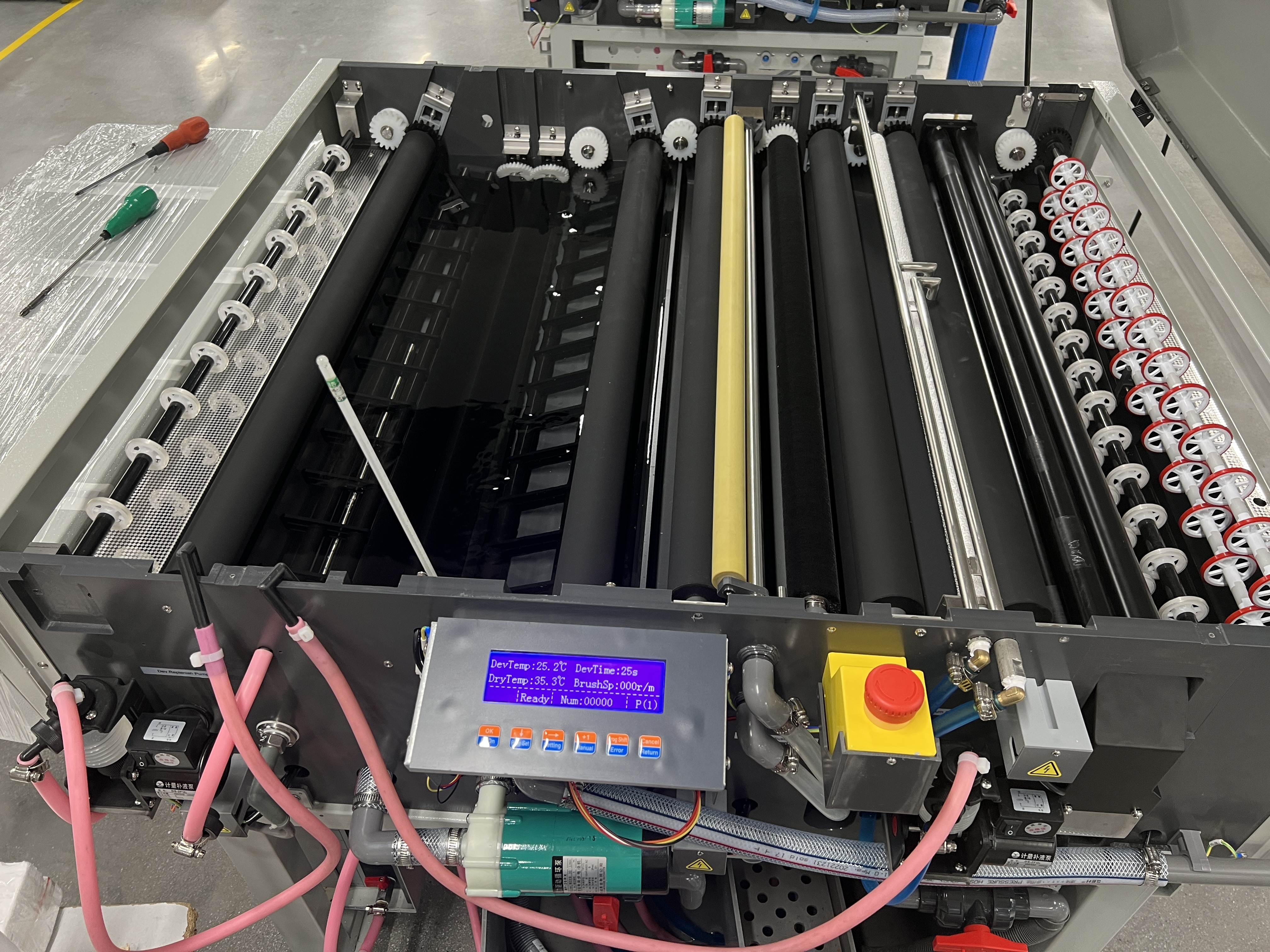

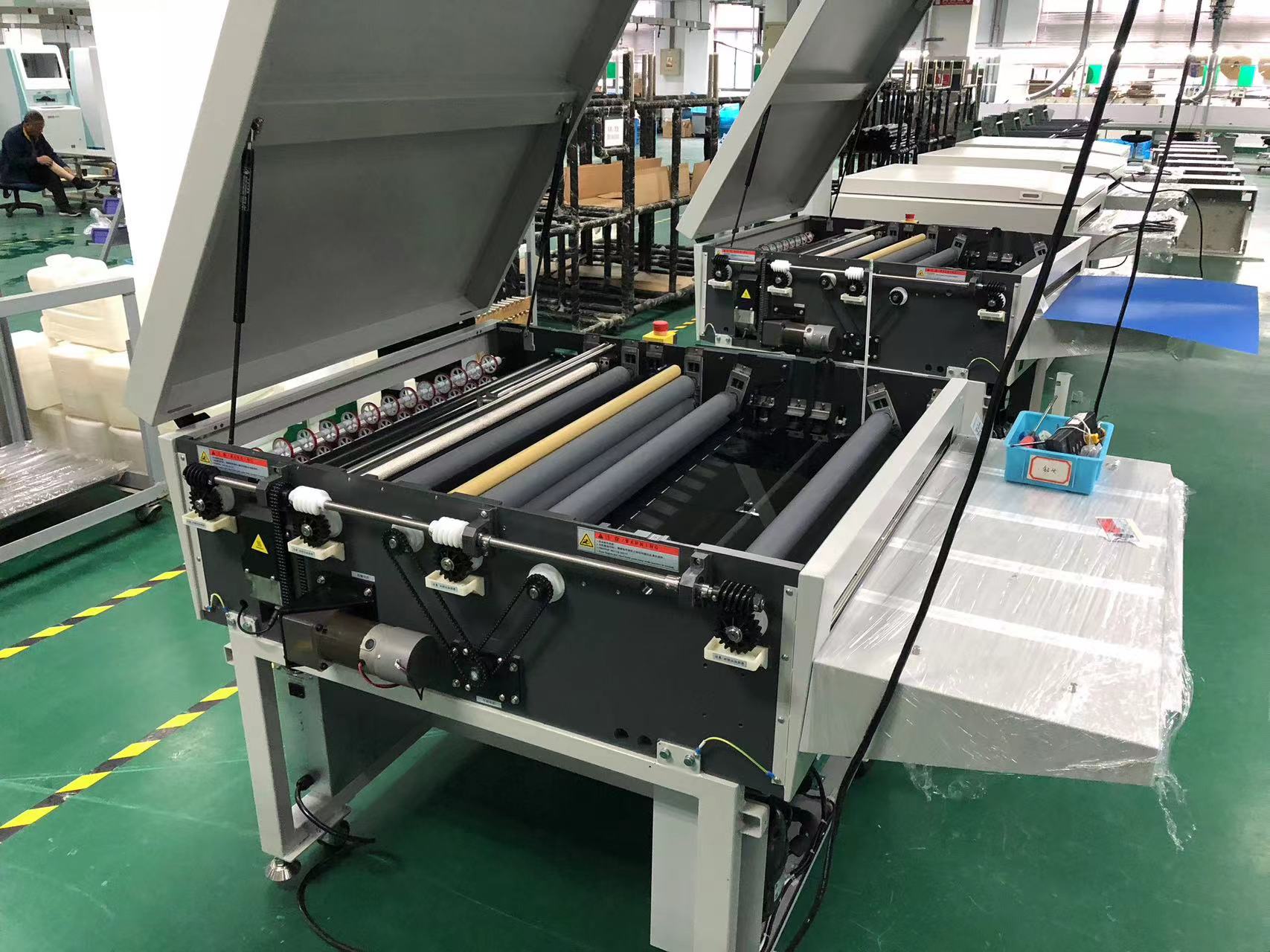

⁃ Immersed roller with stepless speed regulation, permits an automated work cycle.

⁃ Enlarged LED screen, 6-switch operation, user-friendly interface.

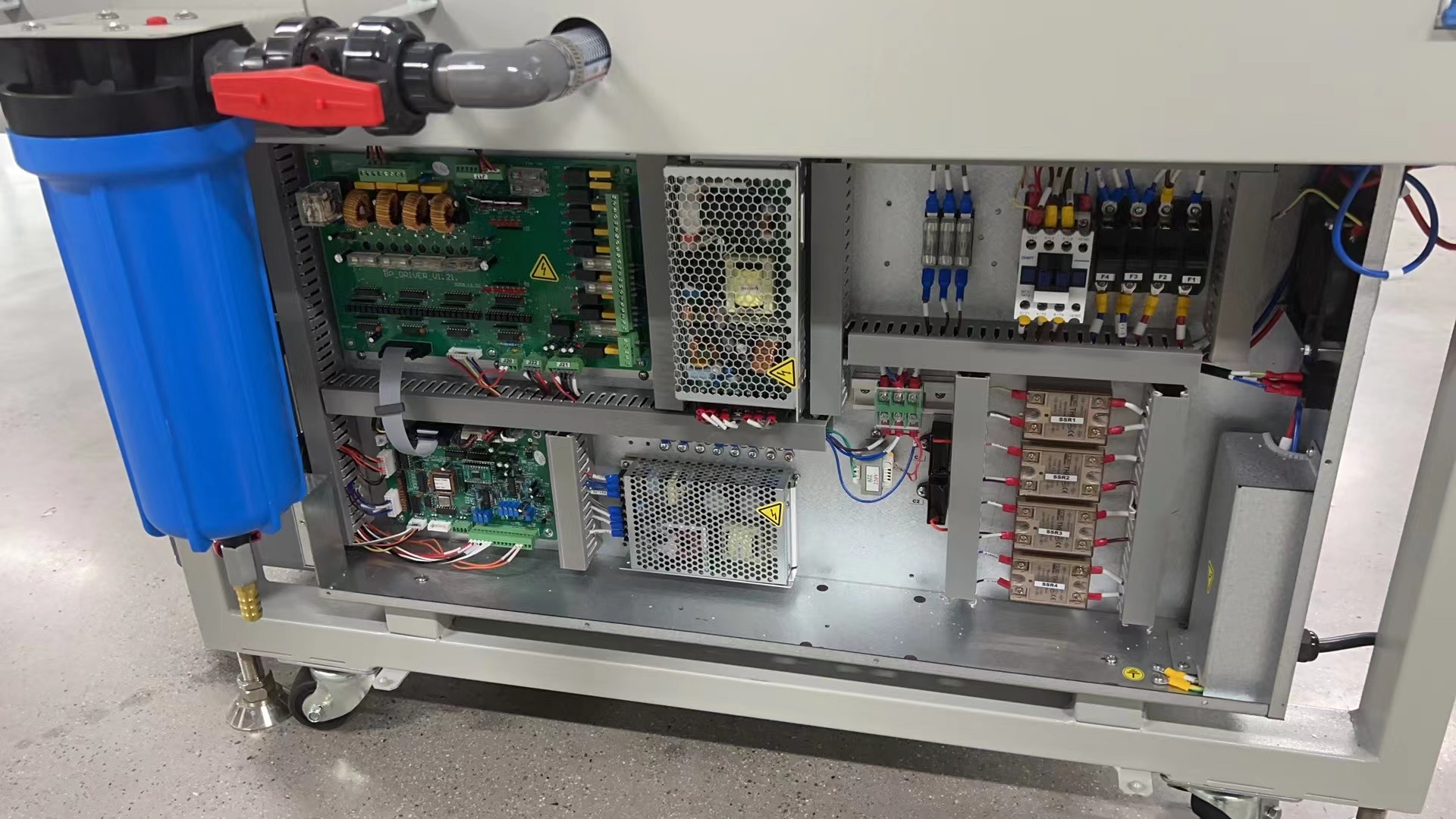

⁃ Advanced system: independent electric, software control system, programmable microprocessor control system, 3 washing options, developing fluid temperature control system that controls the developing temperature at precisely ±0.3℃.

⁃ Developing fluid replenished automatically according to usage, helps to maintain a longer fluid activity.

⁃ Filters can easily be removed and cleaned or replaced in just moments.

⁃ Large capacity developing tank, wide Φ54mm(Φ69mm), acid and alkaline resistant rubber shaft, ensuring durability and stability of the plate.

⁃ Compatible with shaft brushes of different hardness and material.

⁃ Rewash function to obtain optimal layout cleanliness.

⁃ Energy saving and cost reducing automatic sleep mode, automatic glue recycling system, and highly efficient hot air dryer system.

⁃ Upgraded communication interface connects directly with CTP.

⁃ Equipped with emergency switch and alert system to prevent malfunction by overheating, dry heating, and low fluid level.

⁃ Easy maintenance: shaft, brush, circulation pumps are removable.

TECHNICAL PARAMETER

| Model | LQ-CB-90 | LQ-CB-125 |

| Tank volume | 30L | 56L |

| Power supply | 220V 50/60HZ 4KW (max) | 220V 50/60HZ 4KW (max) |

| Plate Width | 880mm(max) | 1250mm (max) |

| Plate Speed | 380mm/min~2280mm/min | 380mm/min~2280mm/min |

| Thickness | 0.15mm-0.40mm | 0.15mm-0.40mm |

| Dev.Time | 10-60sec | 10-60sec |

| Dev.Temp | 20-40℃ | 20-40℃ |

| Dev.Repl | 0-200ml | 0-200ml |

| Dry.Temp. | 40-60℃ | 40-60℃ |

| Brushspeed | 60r/min-120r/min | 60r/min-120r/min |

| Net.Weight | 260kg | 350kg |

| Packing Dimension(L*W*H) | 1700x1600x1350mm | 1900x1700x1300mm |

PICTURES