LQ-TOOL Cutting Rules

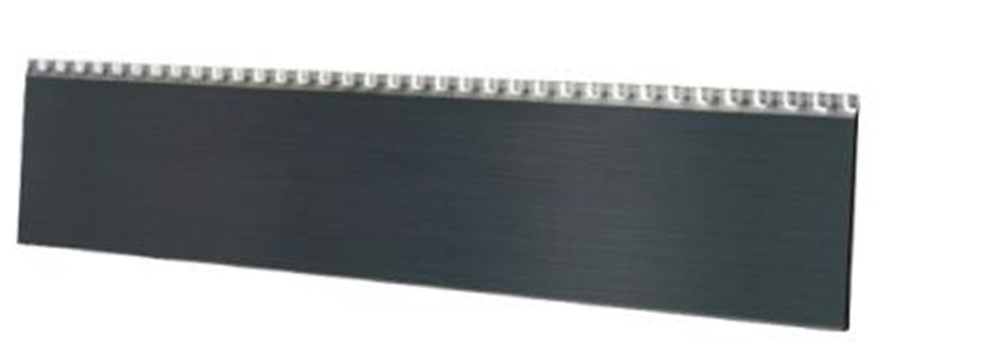

Mirror Cutting Rules (CBM)

● Mirror sharp knife edge

● Two type:<52°,<42°,<30°

● Suitable for cutting paper the quantity is less than 400000pcs

● Can be bend to any geometrical shape.

● Material: DE

● Edge: CB LCB

|

Thickness |

0.53mm(1.5PT) |

0.71mm(2PT) |

|

Height |

23.6mm |

23.8mm |

|

Specification Thickness |

Number |

Color of body |

Angle of edge |

Remark |

|

0.71*23.6/23.8 |

CBM-78 |

Black/White |

30degree |

Edge Hardness HRC55-56° Body hardness HRC 35-36° |

|

0.71*23.6/23.8 |

CBM-88 |

Black/White |

42/45degree |

Edge Hardness HRC57-58° Body hardness HRC 37-38° |

|

0.71*23.6/23.8 |

CBM-98 |

Black/White |

52degree |

Edge Hardness HRC58-59° Body hardness HRC 40-41° |

Grinding Cutting Rules

● Abrasive maching sharp knife edge

● Two type: <52°, <42°, <30°

● Suitable for cutting paper the quantity is less than 200000pcs

● Can be bend to any geometrical shape

Material: KR, DE

Edge: A.CB, B.LCB

|

Thickness |

0.71mm(2PT) |

|

Height |

22.8-30mm |

|

Specification Thickness |

Number |

Color of body |

Remark |

|

0.71mm |

GL-70 |

Gold Body |

Core Hardness Hrc36-37(Soft) |

|

GL-80 |

Core Hardness 38-39(Medium) |

||

|

GLD-70 |

Germany Materials(Soft) |

||

|

GLD-80 |

Germany Materials (Medium) |

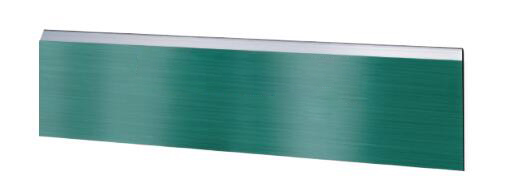

Gillet Cutting Rules(GE)

The edge is polished and sharp,it makes the mechanical capability-change radically.

Used for form-Cutting of the adhesive labels,PVC and other slap-UP goods

Material: CN, DE

Edge: A.CB, B.LCB

|

Thickness |

0.53mm (1.5PT) |

0.71mm (2PT) |

|

Height |

23.6mm |

23.8mm |

|

Specification Thickness |

Number |

Color of body |

Remark |

|

0.71mm |

GE-70 |

Blue-black Body |

Core Hardness Hrc36-37(Soft) |

|

GE-80 |

Blue-black Body |

Core Hardness 38-39(Medium) |

|

|

GED-80 |

Blue-black Body |

Germany Materials |

|

|

1.07mm |

GRB-70 |

Blue-black Body |

Core Hardness Hrc36-37(Soft) |

|

GRB-80 |

Blue-black Body |

Core Hardness 38-39(Medium) |

|

|

GRB-90 |

Blue-black Body |

Core Hardness 40-41(Hard) |

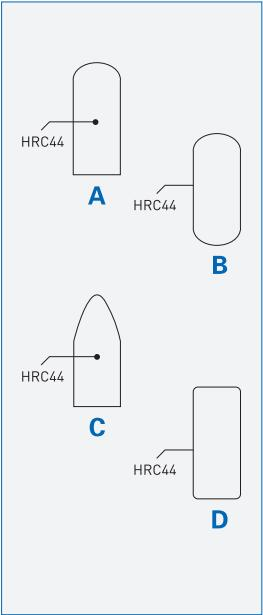

Label rules self-adhesive knife (HL)

Used for forming of all kinds adhesive labels

Can be bend to any geometrical shape

Material: CN JP GM

Edge:A:Single blade knife CB , B:Double blade LCB

|

Thickness |

0.45mm(1.27PT) |

|

Height |

7.0-12.0mm |

|

Specification Thickness |

Number |

Color of body |

Remark |

|

0.45mm |

HL-50 |

White Edge |

Core Hardness HRC41-43 |

|

HL-60 |

Black Edge |

Core Hardness HRC39-40 |

|

|

HL-70 |

White Body |

Core Hardness HRC39-40 |

|

|

HL-80 |

Gold Body |

Core Hardness HRC39-40 |

Special Cutting Rules(KL)

Used for spacers,plastic,fibre and so on,the cutting piece can exceed to 800000pcs

Can be bend to any geometrical shape.

Material: CN JP GM

Edge:A:Single blade knife CB , B:Double blade LCB

|

Specification Thickness |

Number |

Color of body |

Remark |

|

0.71mm |

KL-70 |

Blue-black Body |

Core Hardness HRC 36-37°(Soft) |

Black Cat Cutting(BL)

Used for spacers,plastic,fibre and so on,the cutting piece can exceed to 800000pcs.

Can be bend to any geometrical shape.

Material: CN JP GM

Edge:A:Single blade knife CB , B:Double blade LCB

|

Specification Thickness |

Number |

Color of body |

Remark |

|

0.71mm |

BL-80 |

Blue-black Body |

Core Hardness HRC 36-39°(Medium) |

Perfpration Rules(WL)

1.Square teeth 3teeth/1”,4teeth/1”, 6teeth/1”, 8teeth/1”, {1:1}, 10teeth/1”, 16teeth/1”

2.Used for form-cutting of bill

Material:□CN

Edge: Edge Grinding

|

Thickness |

0.45mm(1.27PT) |

0.71mm(2PT) |

||

|

Height |

8mm |

23.6mm |

23.8mm |

|

|

Size |

1:1;2:1;3:1;6:1;8:1;10:1;12:1;16:1 |

|||

|

Specification Thickness |

Number |

Color of body |

Remark |

|

0.71mm |

WL-90 |

Blue-black Body |

Core Hardness HRC 40-41°(Hard) |

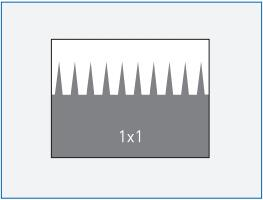

Sharp Teeth Rules (WLS)

1. Double sect cutter

2. Sharp teeth 16teeth/1’’

3. Used for impressing break gradually Specification:510×8.16×0.75mm(one-side edge Business Form rule), (2:1,3:1,1:1)

Material: CN, JP, GM

Edge: CB ,LCB

|

Thickness |

0.71mm(2PT) |

|

Height |

23.0-23.8mm |

|

Specification thickness |

Number |

Explain |

Remark(hardness)requirements |

|

0.71mm |

WLS-90 |

Blue-black Body |

Core Hardness Hrc40~41(Hard) |

One-side Cutter(DEX)

1. Used for form-cutting of aright angle

Material: CN, JP, GM

Edge: CB, LCB

|

Thickness |

0.71mm(2PT) |

1.07mm(3PT) |

|

Height |

22.8-50.0mm |

|

|

Specification thickness |

Number |

Explain |

Remark(hardness)requirements |

|

0.71mm |

DEX-90 |

Blue-black Body |

Core Hardness Hrc40~41(Hard) |

High Cutting Rules(DLX)

1 Used for form-cutting of carton and so on

Material: CN, JP, GM

Edge: CB, LCB

|

Thickness |

0.71mm(2PT) |

1.07mm(3PT) |

|

Height |

30.0-50.0mm |

|

|

Specification Thickness |

Number |

Explain |

Remark |

|

0.71mm |

DLX-80 |

Blue-black Body |

Core Hardness Hrc38~39(Medium) |

|

1.07mm |

DLE-80 |

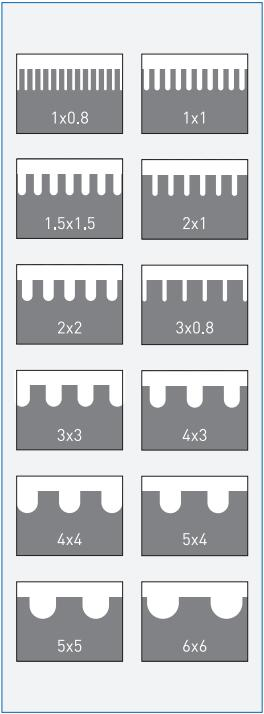

Waved Rules(BL)

1.The height of impressing is made according to your request

2. Used for the box and carton A TYPE 10 PCS/ B TYPE 8PCS /C TYPE 6PCS/D TYPE 4.5PCS/E TYPE 3PCS

Material: CN, JP, GM

EDGE: CB, LCB

|

Thickness |

0.71mm(2PT) |

|

Height |

23.6-23.8mm |

|

Specification Thickness |

Number |

Explain |

Remark |

|

0.71mm |

BL-70 |

Blue-black Body |

Core Hardness Hrc 36~37 |

Creasing Rules

1 The height of impressing made according to your request

2 The thickness is(2PT)0.71mm,(3PT)1.07mm,(4PT)1.42mm,(6PT)2.10mm

Material: CN, JP, GM

Edge: CB, LCB

|

Thickness |

0.71mm(2PT) |

1.07mm(2PT) |

1.42mm(2PT) |

2.10mm(2PT) |

|

Height |

22.8~30.0mm |

|||

|

Specification Thickness |

Number |

Explain |

Remark |

|

0.71mm |

EL-90 |

Blue-black Body |

Core Hardness Hrc 41~43 |

|

ELD-90 |

White Body |

Core Hardness Hrc43~45 |

|

|

EL-70 |

Taiwan |

Core Hardness Hrc38~39(Medium) |

|

|

EL-80 |

Taiwan |

Core Hardness Hrc35~36(Soft) |

|

|

1.07mm |

ELD-70 |

Blue-black Body |

Core Hardness Hrc37 |

|

ELD-80 |

Blue-black Body |

Core Hardness Hrc39 |

|

|

1.42mm |

ELC-70 |

Blue-black Body |

Core Hardness Hrc36 |

|

2.1mm |

ELB-70 |

Blue-black Body |

Core Hardness Hrc35 |

|

0.71mm |

EV-90 |

Blue-black Body |

Core Hardness Hrc41~43(Top Thin Creasing) |

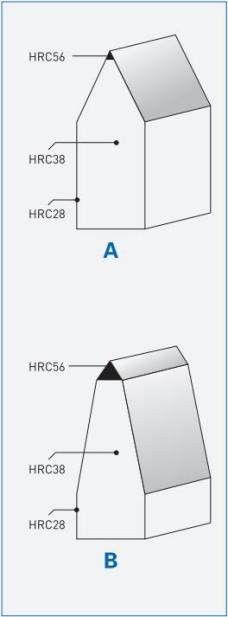

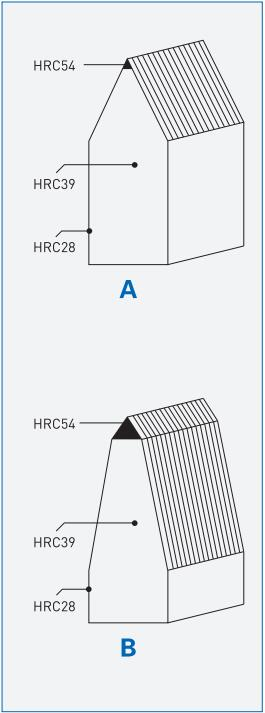

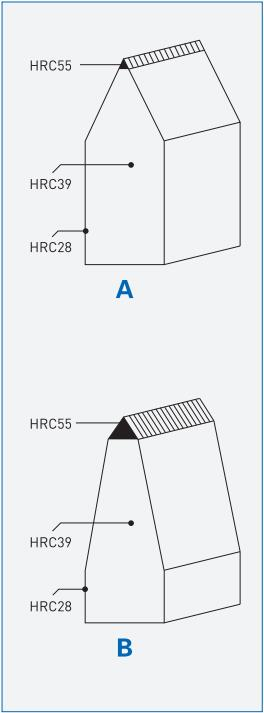

Summary of constituent elements of die cutting knife

| Knife Type | Low-bladed Knife/High-bladed Knife with two-stage/ Single-Sided Knife/ Wave Knife/ Tooth Knife/ Combination knife |

| Steel Type | /S50C/C55 |

| Thickness(mm) | 0.45/0.53/2pt/3pt/4pt/6pt |

| Height(mm) | 7.0/8.0/9.5/12/23.5/23.6/23.7/23.8/30~100mm |

| Body hardness(Hrc) | 33/37/41/45/48/ |

| Blade hardnes(Hrc) | 54/56/58/60/ |

| Blade Angle | ∠30° ∠42° ∠52° |

| Others | High frequency heat treatment hardening, knife edge grinding, knife edge mirror processing. |

Thickness tolerance range of CUTTING rules

| ThicknessExpression | Reference | InternationalStandard | Corporate Standards | |

| Tolerance | Min~Max | |||

| 0.45 | 0.44 | ±0.025 | ± 0.010 | 0.430~0.450 |

| 2PT | 0.71 | ±0.030 | ± 0.010 | 0.700~0.720 |

| 3PT | 1.05 | ±0.040 | ± 0.010 | 1.050~1.070 |

| 4PT | 1.42 | ±0.050 | ± 0.015 | 1.395~1.425 |

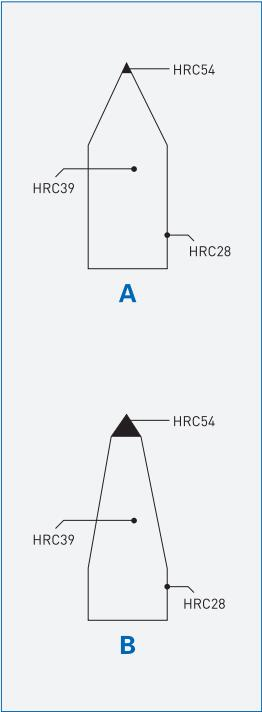

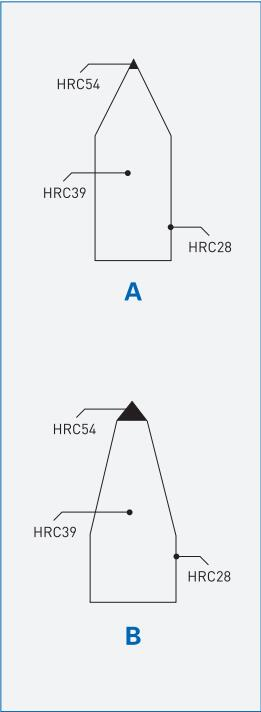

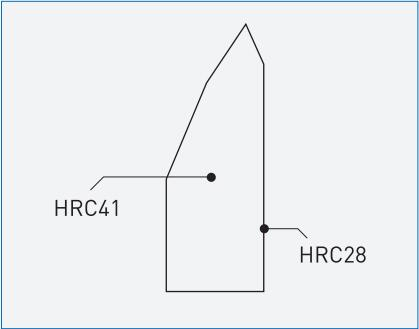

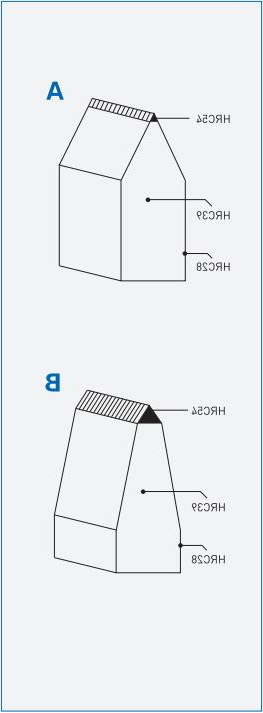

Impact of Blade Angle on Product

Blade Selection

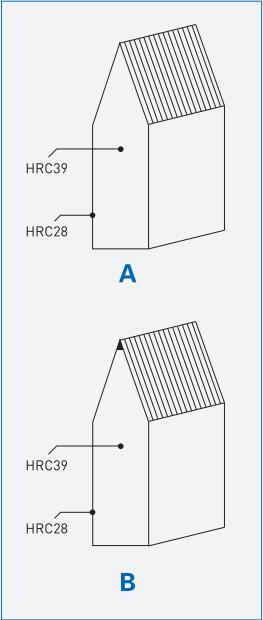

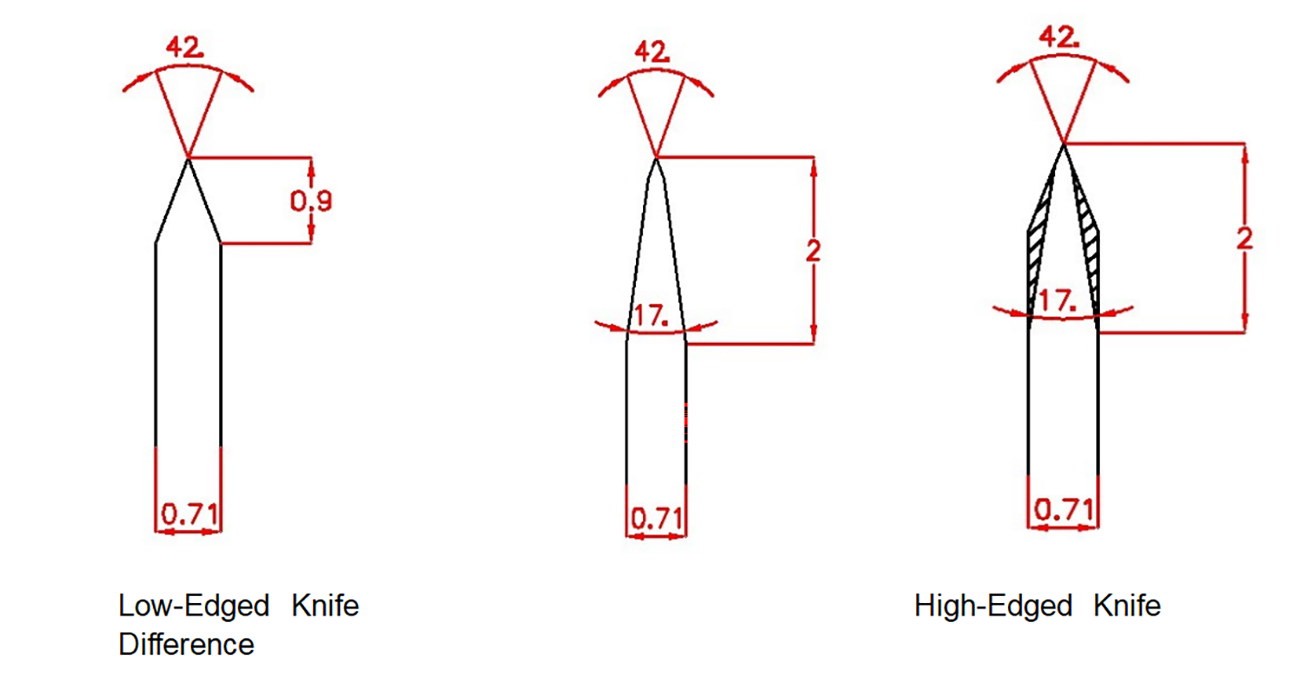

1. Difference of High-edged and Low-edged Knives

The difference between high-edged and low-edged knives is that the high-edged knife is based on the low-edged knife and then grinds off the corners on both sides to make its blade narrower, generally about 2mm.

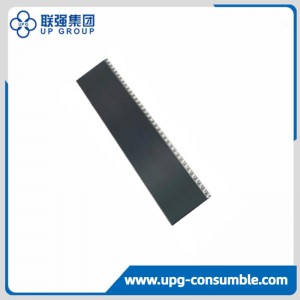

Package

| Thickness | Carton Box quantity | Coil |

| 0.45mm(1.27PT) | 100Pcs/Box | 100M/Coil |

| 0.53mm(1.5PT) | 100Pcs/Box | 100M/Coil |

| 0.71mm(2PT) | 100Pcs/Box | 100M/Coil |

| 1.07mm(3PT) | 70Pcs/Box | 70M/Coil |

| 1.42mm(4PT) | 50Pcs/Box | 50M/Coil |

| 2.10mm(6PT) | 35Pcs/Box | 35M/Coil |

Application area

Die-Cutting for packaging box